Phone

(028) 6258 5368Melt-blown filter

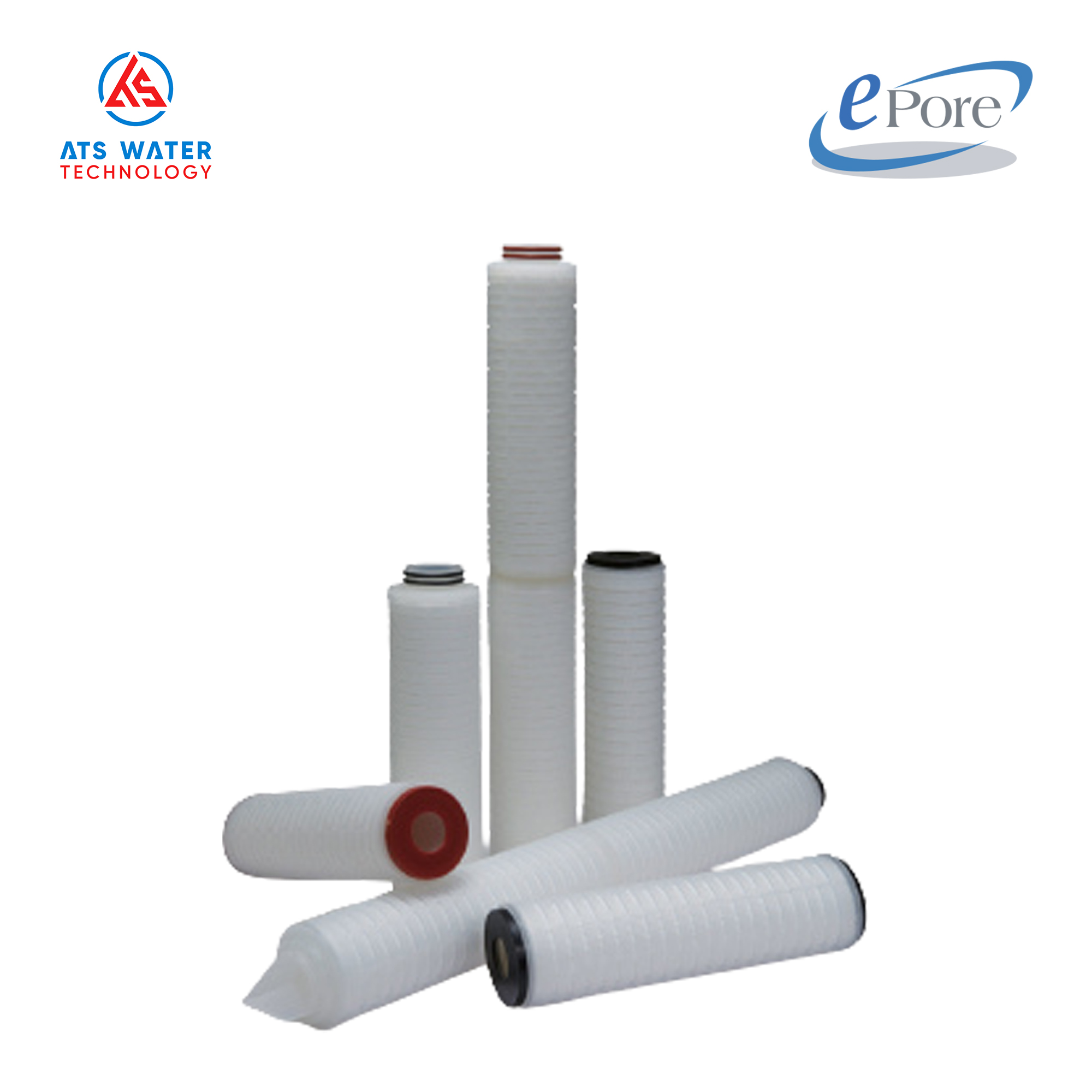

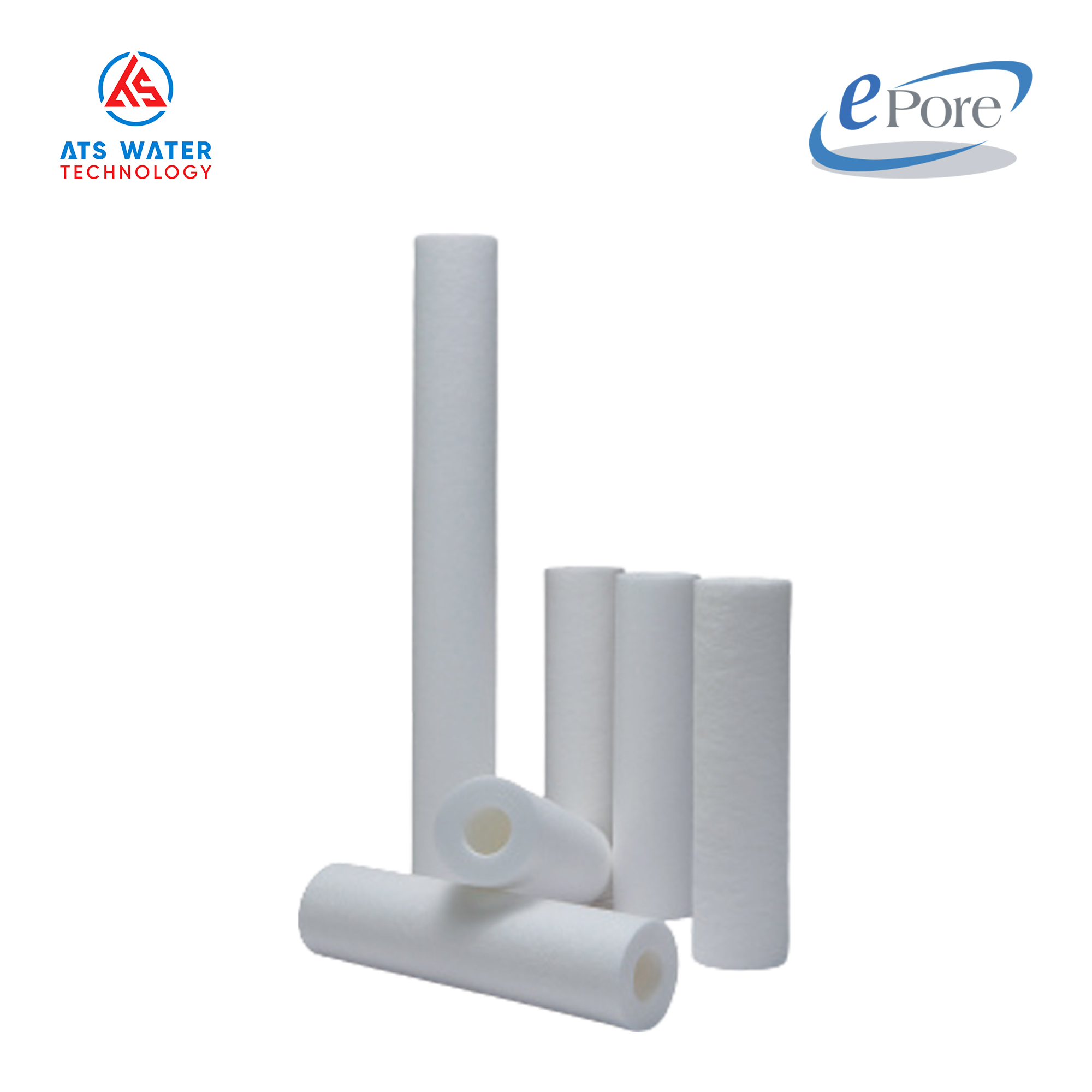

The ePore melt-blown depth cartridge filter is an efficient solution for fine filtration, made from 100% pure polypropylene fibers. Without binders or adhesives, it’s ideal for sensitive applications like pharmaceuticals, hospitals, water treatment, food and beverage, electronics, and semiconductors. The melt-blown process creates a uniform pore structure that effectively removes suspended solids and particulates from water.

Product features

- Depth filtration structure: Using pure polypropylene fibers ensures effective contaminant retention.

- FDA-compliant materials: Safe for food, beverage, and pharmaceutical applications.

- Wide range of micron ratings: Available from 1 to 100 microns to suit diverse filtration needs.

- Consistent quality: Manufactured using advanced melt-blown technology for uniform performance and operational stability.

- Extended service life: Durable media extends replacement cycles, helping reduce operating costs.

Technical specifications

-

Structure

Coreless cartridge

-

Media material

Polypropylene Micro-fiber (100%)

-

Removal ratings

1 – 100 microns

-

Cartridge dimensions

- In diameter: 28 / 30mm

- Out diameter: 60 ~ 63 mm

- Length: 250, 254, 500, 508, 750, 762, 1000, 1016 mm

-

Maximum differential pressure

43.5 psi (3.0 bar) at 25°C

-

Maximum temperature

70°C

ePore’s melt-blown depth cartridge filters are engineered for efficient particle removal and long service life. The melt-blown process (in which molten polypropylene is extruded into fine fibers and layered into a filter matrix) provides a uniform filtration media with a high dirt-holding capacity.

With multiple filtration ratings available, ePore PP melt-blown filters are suitable for industrial and residential applications. Below are detailed specifications and key advantages of this high-performance filter model.

1. Technical specifications of the ePore melt-blown depth cartridge filter

ePore melt-blown depth cartridge filters are available in various lengths and micron ratings to meet diverse filtration needs. They are engineered to remove suspended solids while maintaining optimal flow rates effectively. Please refer to the table below for detailed specifications:

| SPECIFICATION | VALUE | |

|---|---|---|

| Structure | Coreless cartridge | |

| Media material | Polypropylene Micro-fiber (100%) | |

| Removal ratings | 1 – 100 microns | |

| Cartridge dimensions | In diameter | 28 / 30 mm |

| Out diameter | 60 ~ 63 mm | |

| Length | 250, 254, 500, 508, 750, 762, 1000, 1016 mm | |

| Maximum differential pressure | At 25°C | 43.5 psi (3.0 bar) |

| Maximum temperature | 70°C | |

2. Key features and advantages of the ePore melt-blown filter

ePore PP melt-blown filter cartridges are designed to maximize filtration efficiency while reducing operating expenses. Key benefits include:

- High filtration efficiency: Effectively removes suspended solids and fine particles from water.

- Long-lasting performance: Extended service life minimizes downtime and replacement costs.

- Binder-free construction: No adhesives or surfactants; FDA-listed polypropylene ensures safety in sensitive applications.

- Chemical and thermal stability: Performs reliably in demanding operating conditions.

3. Certifications of the ePore melt-blown depth cartridge filter

The filter media used in the ePore melt-blown depth cartridge filter is listed as FDA-compliant, making them suitable for food and pharmaceutical production applications. The melt-blown cartridge filters meet strict international quality and performance standards required in modern industrial environments.

4. Applications of the ePore polypropylene melt-blown filter

Thanks to its effective filtration capabilities and robust design, the ePore melt-blown depth cartridge filter is widely used in various industries:

- Pharmaceutical & healthcare: For sterile water production and medical solution filtration.

- Water treatment: Suitable for industrial and residential water purification systems.

- Food & beverage: Used in drinking water filtration, soft drink production, and fermentation processes.

- Electronics & semiconductors: Applied in the production of ultrapure water for sensitive components.

5. ATS Water Technology – Authorized distributor of the ePore melt-blown depth cartridge filter

ATS Water Technology Co., Ltd. is the authorized distributor of ePore cartridge filters in Vietnam. We supply genuine products, including the ePore polypropylene melt blown filter, that meet strict quality standards, tailored to the requirements of demanding industrial applications.

In addition to product supply, ATS Water Technology offers comprehensive solutions, including system design consulting, water treatment technologies, and optimization services. With extensive experience in water treatment, we are committed to continuous innovation and product enhancement to meet market demands.

Our experienced technical team is always ready to provide expert guidance based on your specific requirements. Whether you’re working with small-scale systems or large industrial operations, we offer the right solution to help you optimize performance and reduce operational costs.

Contact ATS Water Technology today for technical consultation, detailed product information, and competitive pricing.

ATS WATER TECHNOLOGY CO., LTD

- Headquarter: 54/18 Bui Quang La, Ward 12, Go Vap District, HCMC, Vietnam

- Branch office: 77 DHT10B, Dong Hung Thuan Ward, District 12, HCMC, Vietnam

- Consultation and support: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Social media: Facebook | LinkedIn | Zalo Official

TECHNICAL DOCUMENTS

How can we help you?

Solution

Solution  Technology

Technology  Application

Application