Phone

(028) 6258 5368EDI MPure™ modules

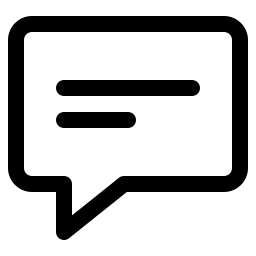

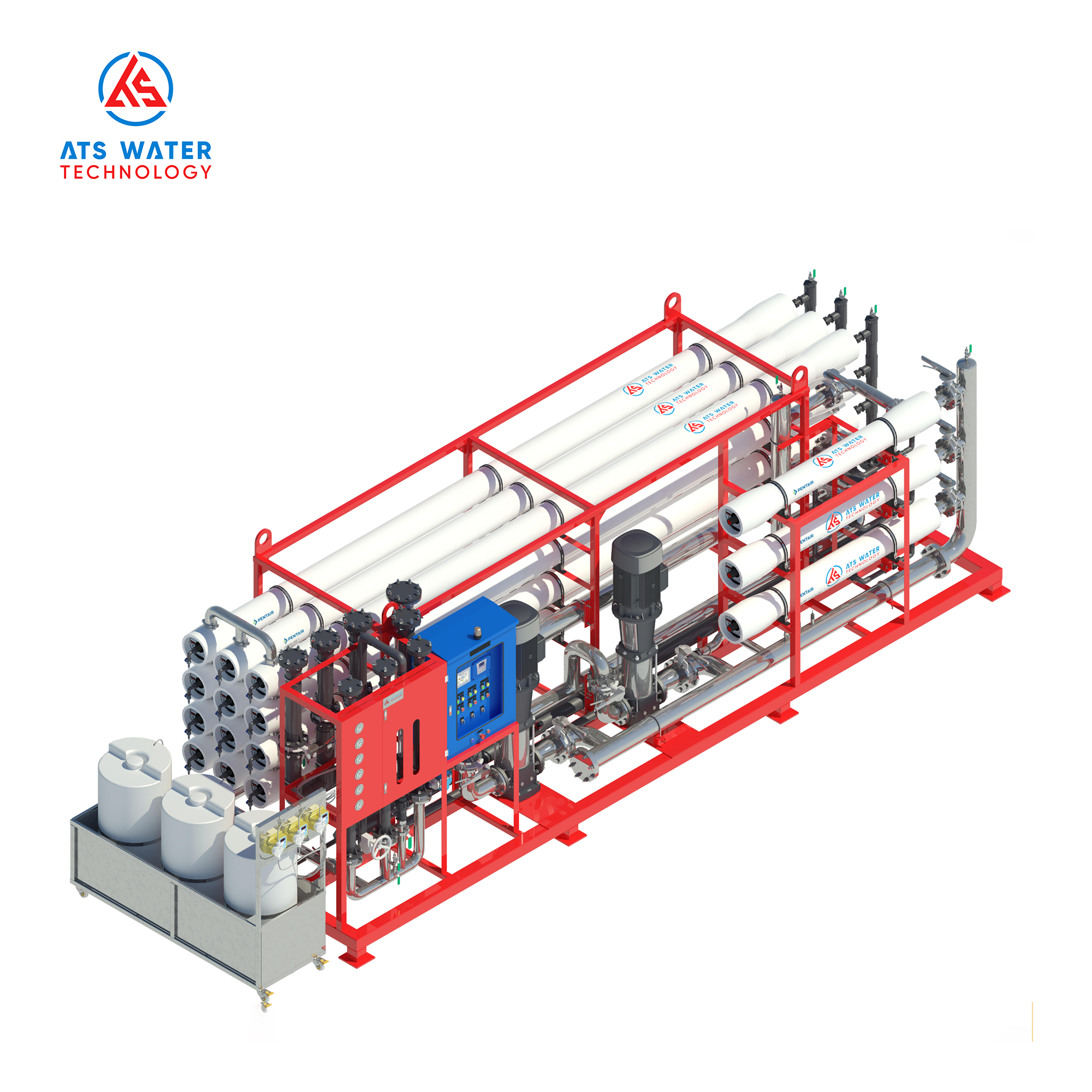

The MEGA MPure™ EDI module stands out by delivering true chemical-free deionization for ultrapure water (UPW), specifically excelling in the power generation, semiconductor, and chemical industries. Leveraging exclusive RALEX® ion-exchange membrane technology, it achieves 16–18 MΩ·cm water purity and eliminates the need for chemical regeneration, offering industry-leading purity and uninterrupted operation. Its notably compact design ensures up to 97.5% water recovery, and high-capacity modules enable exceptional flows of up to 15 m3/h (66.04 gpm). Compared with conventional mixed-bed deionization (MBDI) systems, MPure™ delivers lower operational costs, simpler maintenance, and superior sustainability, making it the premier industrial upgrade in its class.

PRODUCT FEATURES

- Flexible modular connection: Enables easy capacity expansion and system construction with optimized cost efficiency.

-

High throughput: Delivers up to 15 m3/h per module, suitable for various industrial-scale applications.

- Superior deionization efficiency: Achieves a high water recovery rate of up to 97.5%, minimizing wastewater discharge.

- Robust and sustainable design: Prevents both internal and external leaks, ensuring long-term stable operation.

- Compact footprint: Ideal for container installations or space-constrained areas.

- High voltage stability: Maintains consistent water quality even under voltage fluctuations during operation.

- Superior alternative: Uniquely combines proprietary RALEX® membrane technology with a modular design for more efficient, reliable, and cost-effective deionization compared to other currently available EDI modules.

- Certified quality: Holds international certifications including ISO 9001, ISO 14001, ISO 45001, and the Der Grüne Punkt (The Green Dot Certificate).

SPECIFICATIONS

-

Number of cell pairs

6 – 12 – 36

-

Length

584 mm (22.9 inch)

-

Width

251–671 mm (9.9–26.4 inch)

-

Height

811 mm (31.9 inch)

-

Shipping weight

121–330 kg (267–728 lbs)

-

Operating weight

124–350 kg (273–772 lbs)

-

Hydraulic connection of dilute flow

2 ½″ (73 mm) Victaulic

-

Hydraulic connection of concentrate flow

1 ¼″ (42,4 mm) Victaulic

-

Hydraulic connection of electrode flow

¾″ (29,6 mm) Victaulic

The Electrodeionization (EDI) unit uses MEGA’s RALEX® ion-exchange membrane to produce ultrapure water efficiently and sustainably. ATS Water Technology Co., Ltd. provides product specifications, benefits, certifications, and applications.

1. Technical specifications of the MPure™ module

MPure™ EDI modules feature MEGA’s proprietary RALEX® ion-exchange membranes, which set them apart with exceptional mechanical durability and electrochemical performance. The EDI modules uniquely deliver stable operation at low voltage, handle high flow rates, and achieve up to 97.5% water recovery, minimizing wastewater production and post-treatment expenses.

Physical specifications:

| SPECIFICATION | MPURE™ 36 | MPURE™ 12 | MPURE™ 6 |

|---|---|---|---|

| Number of cell pair | 36 | 12 | 6 |

| Dimensions (Length × Width × Height) | 584 × 671 × 811 mm (22.9 × 26.4 × 31.9 inch) | 584 × 335 × 811 mm (22.9 × 13.2 × 31.9 inch) | 584 × 251 × 811 mm (22.9 × 9.9 × 31.9 inch) |

| Shipping weight | 330 kg (728 lbs) | 157 kg (346 lbs) | 121 kg (267 lbs) |

| Operating weight | 350 kg (772 lbs) | 163 kg (359 lbs) | 124 kg (273 lbs) |

| HYDRAULIC CONNECTIONS | |||

| D (Dilute flow) | 2 ½″ (73 mm) Victaulic | ||

| C (Concentrate flow) | 1 ¼″ (42.4 mm) Victaulic | ||

| E (Electrode flow) | ¾″ (26.8 mm) Victaulic | ||

Typical performance:

| SPECIFICATION | MPURE™ 36 | MPURE™ 12 | MPURE™ 6 |

|---|---|---|---|

| Flow nominal | 10 m3/h |

3.33 m3/h |

1.67 m3/h |

| Flow maximum | 15 m3/h |

5 m3/h |

2.5 m3/h |

| Flow minimum | 5 m3/h |

1.67 m3/h |

0.83 m3/h |

| Concentrate flow | > 0.3 m3/h |

> 0.1 m3/h |

> 0.05 m3/h |

| Electrode flow | > 0.1 m3/h (> 0.4 gpm) | ||

| Recovery | < 97.4 % | < 96.2 % | < 94.3 % |

| Feed pressure | < 7 bar (< 102 psi) | ||

| Pressure drop D at nominal flow | 1.1–2.5 bar (16–36 psi) | ||

| Pressure difference D>C | > 0.3 bar (> 4 psi) | ||

| Temperature | 5–40 °C (41–104 °F) | ||

| Current | < 16 A | ||

| Voltage | < 300 V | < 100 V | < 50 V |

| Product water quality | > 17 MΩ·cm* | ||

| Silica removal | > 96 % | ||

*Actual performance will depend on site conditions.

Feed water limitation:

| SPECIFICATION | LIMITATION |

|---|---|

| Feed water source | RO permeate or better |

| Temperature | 5–40 °C |

| pH | 4–10 |

| Total exchange anion (TEA) (CaCO3) | < 25 ppm |

| Total exchange cation (TEC) (CaCO3) | < 25 ppm |

| Free Cl2 | < 0.05 ppm |

| Fe, Mn | < 0.01 ppm |

| Sulfide (H2S) | < 0.01 ppm |

| Total hardness (CaCO3) | < 1 ppm |

| Total organics (TOC) | < 0.5 ppm as C |

| Dissolved silica (SiO2) | < 1 ppm |

2. Advantages of the MPure™ EDI module

The MPure™ EDI module provides continuous UPW for industries with strict quality standards. Its advanced electrodeionization technology maximizes efficiency and delivers safe, cost-effective operation. Key advantages include:

- Flexible modular connectivity: Allows for easy system capacity scaling based on production requirements. Simplifies system integration and lowers capital expenditure.

- High processing capacity: Each EDI module handles up to 15 m3/h, making it scalable for diverse industrial applications.

- Exceptional deionization performance: A water recovery rate of up to 97.5% optimizes EDI module water usage efficiency and significantly lowers operational costs (OPEX).

- Durable and stable operation: The leak-proof design guarantees long-term reliability and stability.

- Compact, space-saving footprint: The EDI module enables installation in containers or restricted areas, maximizing operational space.

- High voltage tolerance and stability: Maintains consistent final water quality despite variations in the EDI module’s operating voltage.

- Compatibility and replacement capabilities: A superior drop-in option engineered for seamless replacement of existing EDI modules, ensuring compliance with stringent OEM specifications while eliminating the need for costly or time-consuming system overhauls.

3. Certifications of the MPure™ EDI module

MEGA MPure™ EDI module meets international standards for quality, safety, and performance in all conditions. These certifications prove the manufacturer’s commitment to world-class water treatment solutions. Certifications include:

- ISO 9001 – Quality management system: Ensures all MPure™ products are manufactured consistently, meeting the highest technical requirements and performance standards.

- ISO 14001 – Environmental management system: Commits to environmentally friendly manufacturing processes, minimizing waste, and ensuring efficient resource utilization.

- ISO 45001 – Occupational health and safety management system: Guarantees a safe working environment for personnel throughout the entire manufacturing and testing process.

- Der Grüne Punkt (The Green Dot Certificate): Confirms MEGA’s responsibility for packaging recycling and disposal, upholding European environmental protection standards.

These certificates confirm that MEGA’s EDI module consistently meets strict performance, reliability, and sustainability standards across various industries.

4. Applications of the MPure™ EDI module

The MPure™ EDI module continuously supplies ultrapure water across many industries, offering an efficient alternative to traditional ion-exchange systems. Applications include:

- Power industry: Supplying ultrapure water for boiler feed, cooling systems, and other high-purity water-demanding equipment.

- Semiconductor and electronics industry: Providing UPW for wafer rinsing, micro-component manufacturing, and other critical processes.

- Chemical industry: Supporting processes requiring continuous streams of ultrapure water, enhancing production efficiency.

- Replacement for mixed-bed systems: Easy-to-connect EDI modules support large-flow-rate systems from 0.8 to 500 m3/h, significantly reducing operational and maintenance costs.

5. ATS Water Technology – Authorized distributor for genuine MPure™ module

ATS Water Technology Co., Ltd. (ATS Water Technology) is the official authorized distributor for MEGA Group’s MPure™ EDI module in Vietnam. MEGA leads in ion-exchange membrane and electro-deionization technology.

Every MPure™ product we distribute is imported directly and includes Certificates of Origin (CO), Certificates of Quality (CQ), and original technical documents. We ensure full traceability and meet international standards.

With a team of engineers specializing in ultrapure water treatment, ATS Water Technology provides technical consulting and support to help clients select the right model and configure equipment for specific applications in power, semiconductor, chemical, and other demanding industrial water treatment systems.

Please contact us today for prompt, effective technical consultation, answers, and support!

ATS WATER TECHNOLOGY CO., LTD

- Head office: 54/18 Bui Quang La, An Hoi Tay Ward, HCMC, Vietnam

- Branch office: 77 DHT10B, Dong Hung Thuan Ward, HCMC, Vietnam

- Consultation and support: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Social media: Facebook | LinkedIn | YouTube

- Quick contact: Zalo Official | Telegram | WhatsApp

TECHNICAL DOCUMENTS

How can we help you?

Solution

Solution  Technology

Technology  Application

Application