Phone

(028) 6258 5368RALEX® HPWU EDI system

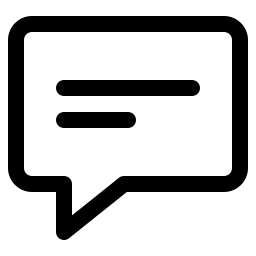

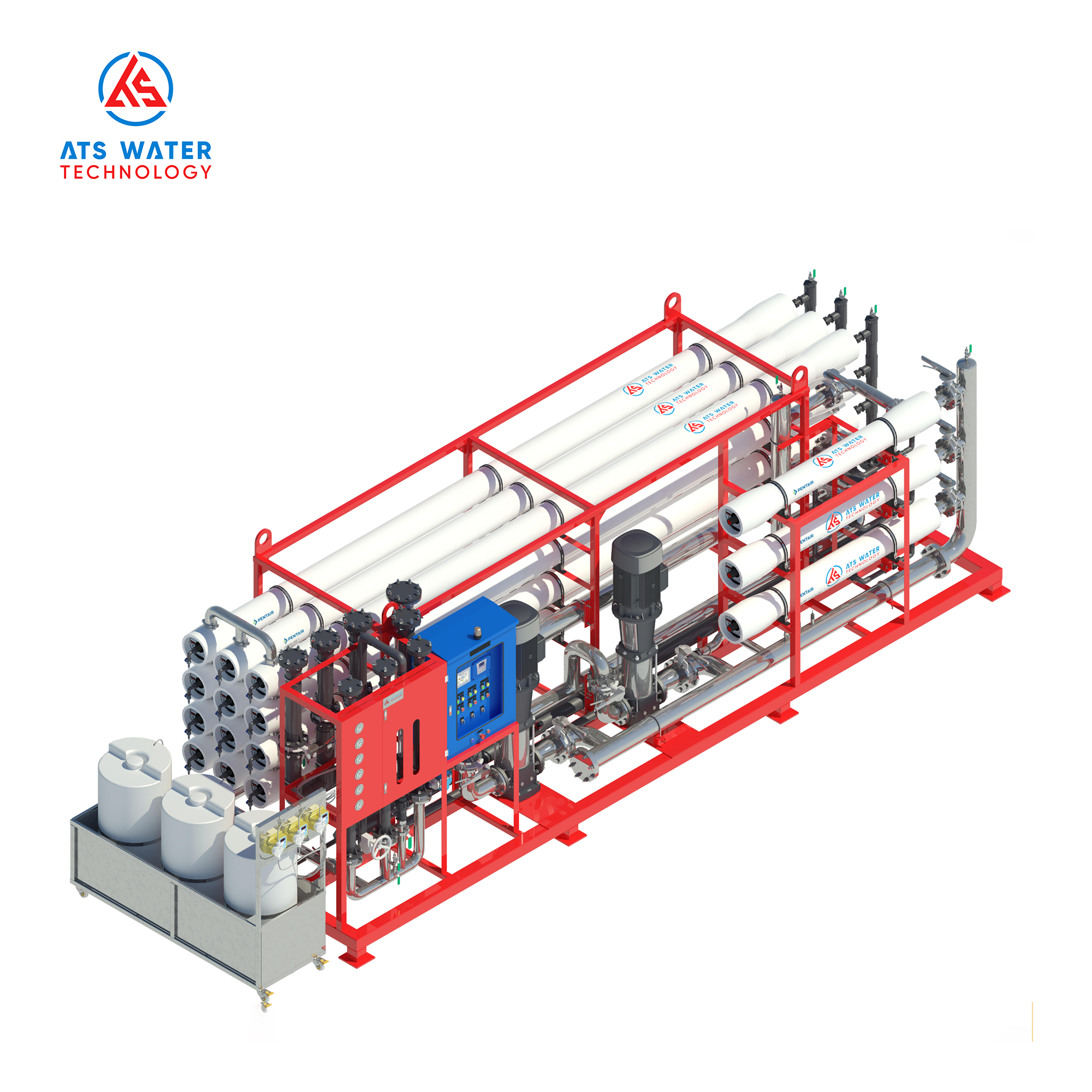

The RALEX® HPWU EDI system utilizes MPure™ modules to produce ultra-pure water with a resistivity of 16-18 MΩ·cm and silica removal exceeding 96%, with scalable system capacities ranging from 0.8 up to over 100 m3/h per skid. The system is fully assembled and factory-tested prior to delivery, significantly reducing on-site installation time and cost. It integrates high-quality components, power supplies, measuring and control instruments, and supports remote monitoring via PLC, allowing seamless integration with upstream and downstream water treatment systems.

PRODUCT FEATURES

- Pre-engineered skid-mounted design, optimized for treatment performance and initial capital cost.

- Modular system architecture enables easy capacity expansion according to system requirements.

- Skid frame manufactured from AISI 304 stainless steel, providing high mechanical strength and excellent corrosion resistance.

- Polypropylene (PP) piping compliant with ultra-pure water standards, minimizing ion leaching and preserving product water quality.

- Integrated pressure and flow sensors with PLC-based control system, supporting fully automatic operation and remote monitoring.

- No isolation transformer required, simplifying electrical configuration and reducing operating costs.

- Product water quality up to 16-18 MΩ·cm, with more than 96% silica removal and effective removal of dissolved ions.

- High water recovery rate up to 97.5%, optimizing energy and water consumption.

-

Treatment capacity from 0.8 up to over 100 m3/h (22–440 gpm) per system.

- Stable operation at 3-7 bar operating pressure, pressure loss of 2-3 bar, and feed water temperature range of 5-40 °C.

- Equipped with CIP ports and automatic divert valves, facilitating cleaning and maintenance.

- Manufactured in compliance with international standards such as ISO 9001, ISO 14001, ISO 45001, and Der Grüne Punkt certification.

SPECIFICATIONS

-

Number of modules

1–9

-

Nominal flow rate

1,67–90 m3/h

-

Product flow rates

0,83–135 m3/h

-

Feed water inlet - hydraulical connection

Female thread G3″ / Flange DN100–150 (4″–6″)

-

Product outlet - hydraulical connection

Female thread G3″ / Flange DN100–150 (4″–6″)

-

Concentrate outlet - hydraulical connection

Female thread ¾″ / Flange DN32 (1 ¼″)

-

Electrode solution outlet - hydraulical connection

Female thread G1″ / Flange DN20 (¾″)

-

CIP inlet / outlet

Flange DN80–125 (3″–5″)

-

Length

1,490–4,760 mm

-

Depth

950–1,500 mm

-

Height

1,655–2,620 mm

-

Operating weight

450–3,930 kg

-

Connected power

2.9–46 kVA

The following section provides an overview of the structure, technical specifications, certifications, and applications of the RALEX® HPWU EDI system, enabling customers to gain a comprehensive understanding of the system performance, application range, and overall value.

1. Structure of the RALEX® HPWU EDI system

The RALEX® HPWU ultra-pure water treatment system is composed of multiple technically integrated components arranged in a rational layout to maximize treatment efficiency and ensure consistent ultra-pure water quality. The system includes the following main components:

- MPure™ modules (up to 36 cells per module)

- Electrical panel with MPure™ DC rectifiers (one rectifier per module)

- Electrically actuated product divert valve

- Concentrate discharge outlet

- Product water outlet

- CIP outlet

- Electrode solution outlet

- Feed water inlet

- CIP solution inlet

- PLC-based control system with touchscreen HMI

- AISI 304 stainless steel skid frame with adjustable feet

- Reject water drain outlet

2. Technical specifications of the RALEX® HPWU EDI system

The technical specifications of the RALEX® HPWU deionization system are optimized in terms of flow rate, operating pressure, and power consumption, ensuring stable operation, high efficiency, and consistent ultra-pure water quality throughout the treatment process. Please refer to the tables below for detailed information.

| SPECIFICATION | 1 × MPURE™36 | 2 × MPURE™36 | 3 × MPURE™36 | 4 × MPURE™36 | 5 × MPURE™36 | 6 × MPURE™36 | 7 × MPURE™36 | 8 × MPURE™36 | 9 × MPURE™36 |

|---|---|---|---|---|---|---|---|---|---|

| Number of modules | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Nominal flow rate | 10 m3/h | 20 m3/h | 30 m3/h | 40 m3/h | 50 m3/h | 60 m3/h | 70 m3/h | 80 m3/h | 90 m3/h |

| Product water flow rate | 5–15 m3/h | 10–30 m3/h | 15–45 m3/h | 20–60 m3/h | 25–75 m3/h | 30–90 m3/h | 35–105 m3/h | 40–120 m3/h | 45–135 m3/h |

| HYDRAULIC CONNECTIONS | |||||||||

| Feed water inlet | DN100 (4″) | DN125 (5″) | DN150 (6″) | ||||||

| Product water outlet | DN100 (4″) | DN125 (5″) | DN150 (6″) | ||||||

| Concentrate outlet | DN32 (1 ¼″) | ||||||||

| Electrode stream outlet | DN20 (¾″) | ||||||||

| CIP inlet / outlet | DN80 (3″) | DN100 (4″) | DN125 (5″) | ||||||

| DIMENSIONS | |||||||||

| Length | 2,440 mm | 3,190 mm | 4,070 mm | 3,330 mm | 4,210 mm | 4,210 mm | 4,760 mm | 4,760 mm | 4,760 mm |

| Width | 1,300 mm | 1,300 mm | 1,470 mm | 1,470 mm | 1,470 mm | 1,470 mm | 1,500 mm | 1,500 mm | 1,500 mm |

| Height | 1,655 mm | 1,655 mm | 1,655 mm | 1,810 mm | 1,810 mm | 1,810 mm | 2,620 mm | 2,620 mm | 2,620 mm |

| Operating weight | 700 kg | 1,120 kg | 1,500 kg | 1,865 kg | 2,270 kg | 2,640 kg | 3,190 kg | 3,560 kg | 3,930 kg |

| Apparent power | 5.26 kVA | 10.3 kVA | 15.5 kVA | 20.5 kVA | 25.5 kVA | 30.5 kVA | 35.8 kVA | 41 kVA | 46 kVA |

| SPECIFICATION | 1 × MPURE™ 6 | 1 × MPURE™ 12 |

|---|---|---|

| Number of modules | 1 | 1 |

| Nominal flow rate | 1.67 m3/h | 3.33 m3/h |

| Product water flow rate | 0.83–2.5 m3/h | 1.67–5.0 m3/h |

| HYDRAULIC CONNECTIONS | ||

| Feed water inlet | Female thread G 3″ | Female thread G 3″ |

| Product water outlet | Female thread G 3″ | Female thread G 3″ |

| Concentrate outlet | Female thread G 1 ¾″ | Female thread G 1 ¾″ |

| Electrode stream outlet | Female threadg G 1″ | Female threadg G 1″ |

| CIP inlet / outlet | – | – |

| DIMENSIONS | ||

| Length | 1,490 mm | 1,490 mm |

| Width | 950 mm | 950 mm |

| Height | 1,817 mm | 1,817 mm |

| Operating weight | 450 kg | 490 kg |

| Connected load | 2.9 kVA | 3.16 kVA |

3. Advantages of the RALEX® HPWU EDI system

The RALEX® HPWU EDI system delivers stable performance, easy operation, and high energy efficiency. Its flexible design and scalable flow capacity allow it to meet a wide range of ultrapure water treatment requirements. The key advantages of the system are outlined below:

- Outstanding treatment performance: Produces ultrapure water with a resistivity of 16-18 MΩ·cm, removes more than 96% of silica and the majority of dissolved ions, meeting the stringent requirements of the power, semiconductor, and pharmaceutical industries.

- Optimized capital investment: The pre-engineered design shortens project implementation time and reduces installation and operating costs.

- Flexible modular structure: Allows easy capacity expansion and seamless integration with RO, UF, pretreatment, and post-treatment systems.

- High mechanical durability: Skid frame manufactured from AISI 304 stainless steel, providing excellent corrosion resistance in industrial environments.

- Materials suitable for ultrapure water: Polypropylene (PP) piping minimizes ion leaching, preserving water purity and ensuring stable product water quality.

- Automated and intelligent operation: Integrated pressure and flow sensors with a centralized PLC control system enable automatic operation and convenient remote monitoring via a digital interface.

- Optimized electrical design: No isolation transformer required, simplifying the electrical configuration while reducing energy consumption and operating costs.

- High energy efficiency: Water recovery rate of up to 97.5%, minimizing wastewater discharge and electrical power consumption.

- Stable operating conditions: Reliable performance at operating pressures of 3-7 bar, pressure drop of 2-3 bar, and feed water temperatures from 5-40°C, ensuring long-term operational stability.

- Easy maintenance: Equipped with CIP ports and automatic divert valves, allowing safe, fast, and efficient cleaning and maintenance.

- International certifications: Certified to ISO 9001, ISO 14001, ISO 45001, and Der Grüne Punkt, confirming product quality, sustainability, and compliance with European environmental standards.

4. Certifications of the RALEX® HPWU EDI system

The RALEX® HPWU ultrapure water treatment system is certified in accordance with international standards for quality, environmental management, and occupational safety. These certifications ensure reliability and performance across industrial and research applications, including:

- ISO 9001 – Quality management system: Ensures that all design, manufacturing, and inspection processes are consistently controlled and meet the highest quality standards.

- ISO 14001 – Environmental management system: Demonstrates a commitment to environmentally responsible manufacturing, reduced emissions, and optimized resource utilization.

- ISO 45001 – Occupational health and safety management system: Ensures a safe working environment for employees while maintaining stable and reliable production operations.

- Der Grüne Punkt (The Green Dot) certification: Confirms MEGA’s compliance with European Union regulations on sustainable packaging, recycling, and waste management, contributing to environmental protection.

5. Applications of the RALEX® HPWU EDI system

With its ability to produce stable and continuous ultrapure water, the RALEX® HPWU EDI system is suitable for a wide range of applications requiring the highest water quality, including:

- Energy and power generation: Production of make-up water for steam turbines, high-pressure boilers, and power generation systems requiring water purity above 16 MΩ·cm.

- Chemical and petrochemical industries: Supply of ultrapure water for formulation, catalytic processes, and reactor cleaning, minimizing ionic contamination that could affect product quality.

- Microelectronics and semiconductor manufacturing: Used in chip and electronic component production, especially in silicon wafer cleaning processes prior to circuit layer deposition, where extremely low conductivity and near-zero silica content are critical.

- Pharmaceutical and biomedical industries: Production of purified water (PW, HPW) for formulation, equipment rinsing, and laboratory testing in GMP-compliant processes.

- Complete water treatment systems: Easily integrated with pretreatment units (RO, UF) and post-treatment systems (mixed bed, UV, TOC), suitable for both new installations and system retrofits.

6. Authorized supplier of the RALEX® HPWU EDI system

ATS Water Technology Co., Ltd. is proud to be the authorized distributor of the RALEX® HPWU EDI deionization system from MEGA (Czech Republic) in Vietnam—a world-leading manufacturer in ion-exchange membrane and electrodialysis technologies.

As a strategic partner of MEGA, ATS Water Technology supplies fully imported RALEX® HPWU EDI systems, ensuring outstanding treatment performance, product water resistivity of 16-18 MΩ·cm, and high operational stability under continuous operation. All products are internationally certified and suitable for the most demanding ultrapure water systems in the power, electronics, semiconductor, and chemical industries.

With a team of engineers deeply experienced in water treatment technologies, ATS Water Technology not only provides genuine equipment but also supports customers with technical consulting, configuration selection, and system integration in full compliance with international standards.

Contact ATS Water Technology today for fast and professional technical support.

ATS WATER TECHNOLOGY CO., LTD

- Head office: 54/18 Bui Quang La, An Hoi Tay Ward, HCMC, Vietnam

- Branch office: 77 DHT10B, Dong Hung Thuan Ward, HCMC, Vietnam

- Consultation and support: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Social media: Facebook | LinkedIn | YouTube

- Quick contact: Zalo Official | Telegram | WhatsApp

TECHNICAL DOCUMENTS

How can we help you?

Solution

Solution  Technology

Technology  Application

Application