Phone

(028) 6258 5368SAF-X screen filter

The auto self-cleaning SAF-X filter represents the next generation from Amiad’s acclaimed SAF series, engineered to deliver enhanced filtration efficiency and operational stability in industrial water treatment applications. This advanced unit features automatic backwash with suction-scanning cleaning technology, providing superior cleaning performance without system downtime. The SAF-X offers robust, high-precision operation across filtration grades from 10-800 microns, supporting diverse applications from cooling tower side-stream filtration to membrane system pre-treatment.

PRODUCT FEATURES

- Enhanced design: Easy operation, simplified maintenance, and versatile installation options

- Advanced self-cleaning mechanism: Automated suction-scanning technology triggered by differential pressure or timer settings

- Uninterrupted filtration: Maintains consistent flow rates throughout cleaning cycles

- Large filtration surface area: Effectively processes water sources with high total suspended solids (TSS) concentrations

- Operational efficiency: Minimal backwash water usage and low operating pressure requirements

- Robust construction: 316 stainless steel screen and epoxy-coated housing deliver exceptional durability in demanding environments

- International certifications: Compliant with CE, UKCA, ACS, NSF/ANSI 61 standards

SPECIFICATIONS

-

Maximum flow rate (130µ)

80 – 240 m3/h (352 – 1,060 gpm)

-

Design pressure

10 bar (150 psi)

-

Minimum operating pressure

2 bar (30 psi)

-

Working temperature

4 – 50°C (39.2 – 122°F)

-

Filtration area

1,500 – 4,500 cm2 (233 – 700 in2)

-

Inlet / Outlet diameter

2 – 8″ (50 – 200 mm)

-

Filter housing

10″ (250 mm)

-

Weight: empty/operational (per inlet/outlet diameter)

2 – 8″ (50 – 200 mm): 108 – 247 kg (238 – 543 lb)

-

Standard filtration degrees

10 – 800 micron (0.01 – 0.8 mm)

To help customers fully understand the performance capabilities, technology, and practical applications of the SAF-X automatic self-cleaning screen filter, this comprehensive guide details its construction, operating principles, technical specifications, key advantages, international certifications, and specific application areas. This information will help customers confidently evaluate and select configurations suitable for their specific water treatment requirements.

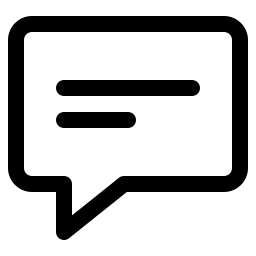

1. Construction and operating principles of SAF-X screen filter

The SAF-X filter integrates optimized mechanical design with advanced self-cleaning technology, ensuring reliable, efficient operation across varied conditions. For enhanced understanding, detailed construction illustrations are provided below:

For a visual demonstration of the equipment’s operating principles, refer to the accompanying video. This presentation illustrates water flow through the filter screen layers, sediment accumulation patterns, and the control system’s activation of automatic backwash cycles using suction-scanning technology. This advanced solution delivers rapid, efficient cleaning without interrupting filtration flow.

2. Technical specifications of SAF-X screen filter

The equipment employs 316 stainless steel screens available in filtration grades from 10 to 800 microns. Three primary models — SAF-X 1500, SAF-X 3000, and SAF-X 4500 — offer progressively larger filtration areas and flow capacities ranging from 80 to 240 m3/h. A detailed technical specification table for the SAF-X screen filter is available for customer reference.

| SPECIFICATION | SAF-X 1500 | SAF-X 3000 | SAF-X 4500 |

|---|---|---|---|

| GENERAL DATA | |||

| Maximum flow rate (130µ) | 80 m3/h |

160 m3/h |

240 m3/h |

| Design pressure | 10 bar (150 psi) | ||

| Minimum operating pressure | 2 bar (30 psi) | ||

| Working temperature | 4 – 50°C (39.2 – 122°F) | ||

| Filtration area | 1,500 cm2 |

3,000 cm2 |

4,500 cm2 |

| Inlet / Outlet diameter | 2” (50 mm) 3” (80 mm) 4” (100 mm) |

3” (80 mm) 4” (100 mm) 6” (150 mm) |

4” (100 mm) 6” (150 mm) 8” (200 mm) |

| Filter housing | 10” |

||

| Weight: empty/operational (per inlet/outlet diameter) | 2” (50 mm): |

3” (80 mm): |

4” (100 mm): |

| 3” (80 mm): |

4” (100 mm): |

6” (150 mm): |

|

| 4” (100 mm): |

6” (150 mm): |

8” (200 mm): |

|

| FLUSHING DATA | |||

| Exhaust valve | 50 mm (2”) | ||

| Flushing time | 20 seconds | ||

| Reject water volume per flush cycle | 39 liters |

78 liters |

117 liters |

| Flushing flow rate | 7 m3/h |

14 m3/h |

21 m3/h |

| ELECTRONIC CONTROL | |||

| Control voltage | 24V AC or DC | ||

| Electric motor | 1/4 HP (0.18 Kw) 50/60 Hz | ||

| Rated operation voltage | Three-phase, 230/400/460V, 50/60 Hz Single-phase, 110/220V, 50/60 Hz |

||

| Current consumption | 0.6 Amp. (with three-phase 400V) | ||

| CONSTRUCTION MATERIALS | |||

| Filter housing and lid | Epoxy-coated carbon steel 37-2 (Stainless steel 316 available on request) |

||

| Screens | Stainless steel 316 | ||

| Cleaning mechanism | Stainless steel 316, POM, PVC | ||

| Exhaust valve | Epoxy-coated cast iron, natural rubber | ||

| Seals | Synthetic rubber | ||

| Control | Aluminium, brass, stainless steel, PVC | ||

3. Key advantages of SAF-X screen filter

Amiad’s SAF-X screen filter stands out through innovative design and delivers substantial operational benefits:

- Simplified maintenance: Simple design featuring a hinged lid enables straightforward component inspection and cleaning

- Intelligent automation: Self-cleaning cycles activate automatically based on pressure differential or programmable intervals, ensuring consistent system cleanliness and stable operation.

- Installation versatility: Allows installation of measurement and control components on either side of the filter, adapting to various system layouts.

- Long-term reliability: Built for continuous operation with consistent performance, utilizing superior corrosion-resistant materials like 316 stainless steel.

- Suitable for various applications: Particularly effective for challenging water sources with high suspended solids content.

- Economic operation: Reduces maintenance demands while conserving backwash water and energy, supporting cost-effective long-term operation.

- Comprehensive certifications: Certified to internationally recognized standards, including CE, UKCA, ACS, NSF/ANSI 61.

4. Certifications of SAF-X screen filter

The SAF-X screen filter meets rigorous international quality and safety standards:

- CE Marking: Confirms compliance with European health, safety, and environmental protection requirements – View CE certification of the SAF-X screen filter.

- UKCA Marking: Demonstrates conformity with applicable standards for the Great Britain market – View UKCA certification of the SAF-X screen filter.

- ACS Standard: Validates safety for potable water contact per French and European standards – View ACS certification of the SAF-X screen filter.

- NSF/ANSI 61 Standard: Ensures material safety in potable water systems, certified by NSF International (USA) – View NSF/ANSI 61 certification of the SAF-X screen filter.

5. Applications of SAF-X screen filter

The SAF-X’s efficient cleaning capability, adaptable design, and robust construction make it suitable across multiple industries and water treatment scenarios:

- Cooling tower sidestream filtration: Maintains heat exchanger cleanliness, improving efficiency and extending equipment life.

- UF/RO pre-treatment: Reduces SDI (Silt Density Index), prolonging membrane lifespan and reducing operational costs.

- Industrial wastewater treatment: Effectively filters high-TSS effluent for recirculation or discharge applications.

- Aquaculture and agricultural water treatment: Ensures optimal input water quality for modern aquaculture facilities and precision irrigation.

- Critical equipment protection: Safeguards spray nozzles, pumps, valves, and heat exchangers requiring consistently clean water supply.

6. Authorized distributor of SAF-X screen filter

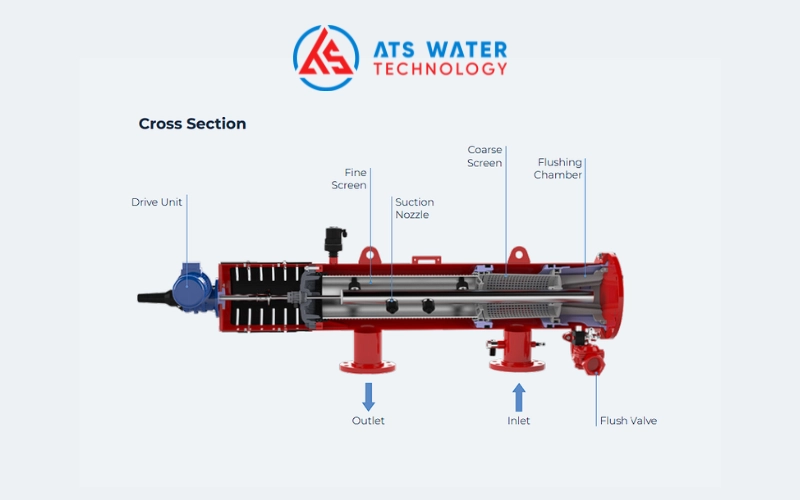

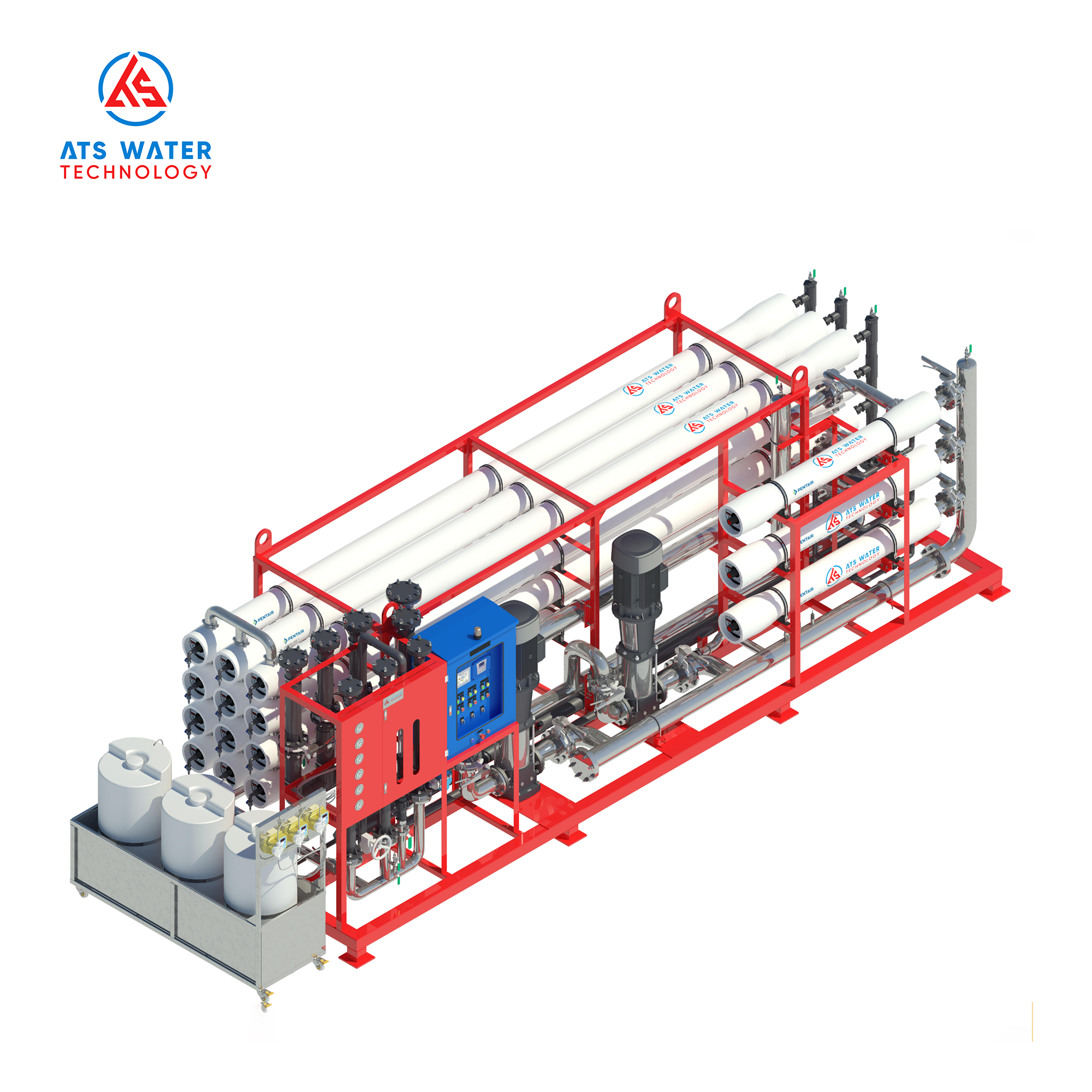

ATS Water Technology Co., Ltd. proudly serves as Amiad’s official distributor in Vietnam. We specialize in consulting, designing, and providing advanced water treatment technology solutions and equipment (including Amiad SAF-X self-cleaning filters). Our expertise spans diverse sectors, including municipal water supply, industrial processing, agriculture, food and beverage, oil and gas, and specialized applications.

Our experienced engineering team brings deep water filtration technology expertise, providing comprehensive consulting services to help customers select optimal equipment for their specific technical requirements and operational conditions.

Committed to customer success, ATS Water Technology delivers effective, tailored solutions for every water treatment challenge, from initial equipment selection through complete system implementation and ongoing maintenance support. Contact us today for expert technical consultation and customized water treatment solutions.

ATS WATER TECHNOLOGY CO., LTD

- Head office: 54/18 Bui Quang La, An Hoi Tay Ward, HCMC, Vietnam

- Branch office: 77 DHT10B, Dong Hung Thuan Ward, HCMC, Vietnam

- Consultation and support: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Social media: Facebook | LinkedIn | YouTube

- Quick contact: Zalo Official | Telegram | WhatsApp

How can we help you?

Solution

Solution  Technology

Technology  Application

Application