Phone

(028) 6258 5368NanoH2O (LG Chem) - RO membranes

NanoH2O (LG Chem) - RO membranes

NanoH2O™ Commercial & Industrial RO Membranes

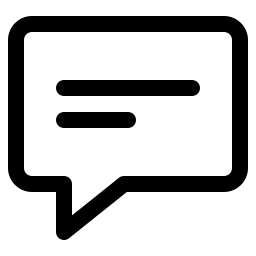

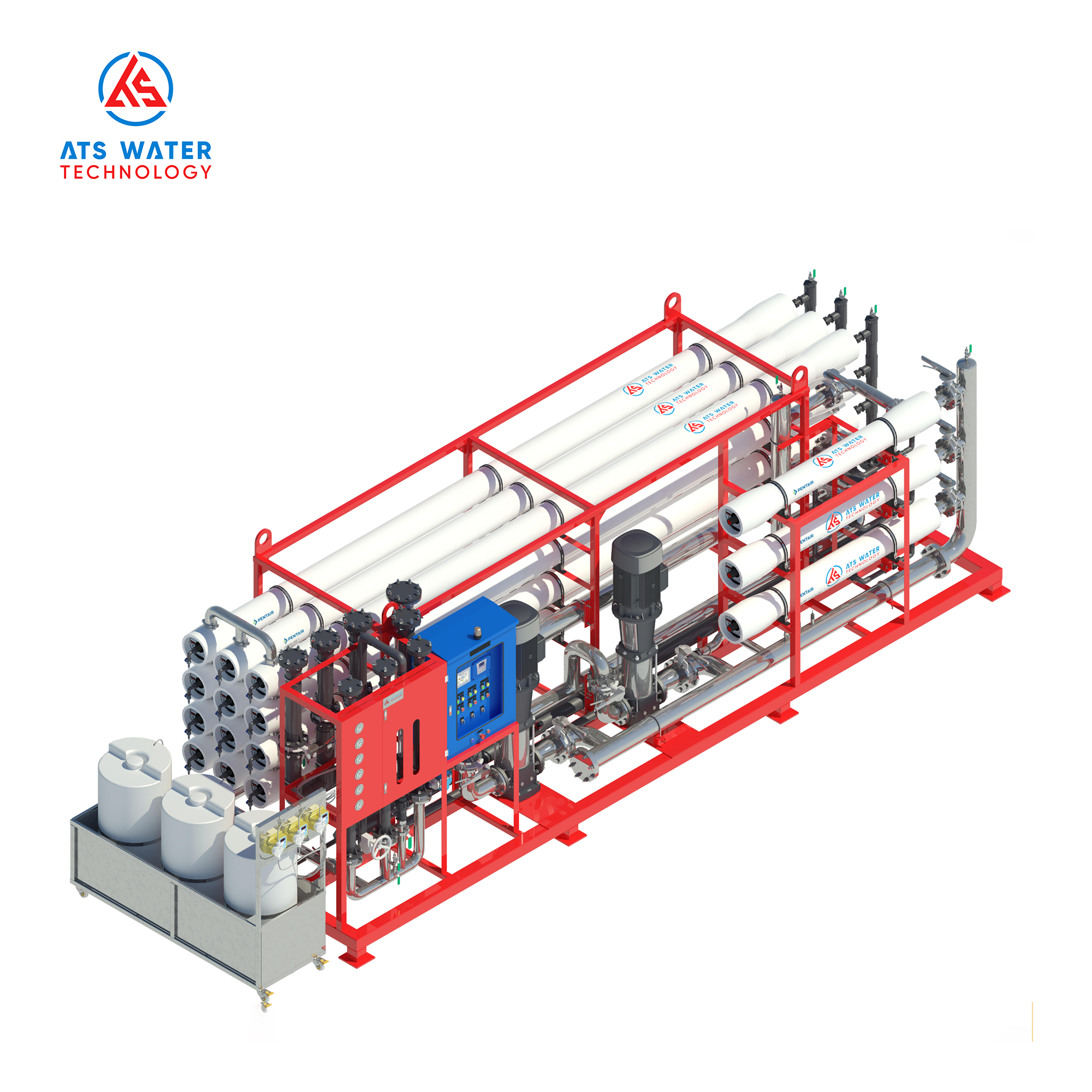

Reverse osmosis (RO) membranes are widely used in industrial applications due to their exceptional ability to remove impurities effectively. Among these, LG Chem’s NanoH2O™ commercial and industrial RO membranes stand out with their advanced TFN technology, offering high filtration performance and salt rejection rates of up to 99.89%, meeting diverse water treatment needs.

1. What are RO membranes?

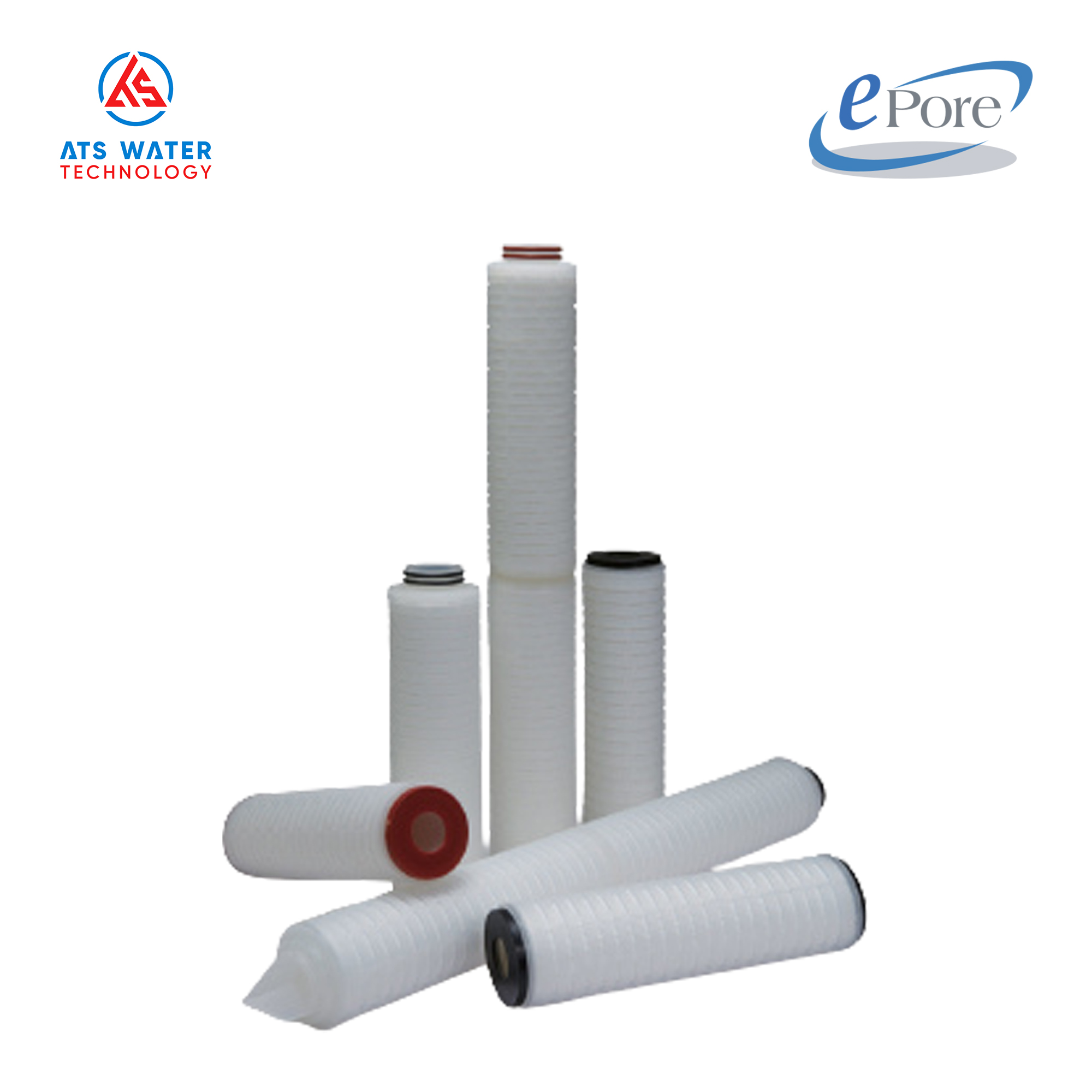

RO membrane elements are water filtration membranes that use reverse osmosis technology. This mechanism effectively removes contaminants larger than 0.0001 microns, eliminating 95–99% of dissolved salts (ions), particles, colloids, organic matter, bacteria, and viruses from water sources.

The spiral wound RO membrane module structure includes three main components: a semi-permeable membrane, a central permeate tube, and a feed spacer.

RO membranes are an optimal solution for most industrial, commercial and domestic water treatment applications, including:

- Drinking water production

- Brackish water treatment

- Pretreatment for semiconductor, medical, pharmaceutical industries and etc.

- Water treatment in the F&B sector

- Wastewater reuse

- Residential water purification

- Seawater desalination

RO membranes available on the market today are highly diverse, designed for various purposes. They are categorized based on size, origin, filtration capacity, membrane material, and application for specific water sources. Among these, classification by application is the most common, consisting of:

- BWRO (Brackish Water Reverse Osmosis): Designed to treat brackish water, also widely used for other purposes such as drinking water production and industrial processes.

- SWRO (Seawater Reverse Osmosis): Engineered for seawater treatment, commonly used in desalination systems to produce fresh water from seawater.

- TWRO (Tap Water Reverse Osmosis): Used for tap water treatment, suitable for residential filtration systems and domestic water purification.

2. NanoH2O™ industrial RO membranes by LG Chem

In 2006, NanoH2O™ in the U.S. introduced the revolutionary Thin Film Nanocomposite (TFN) technology for RO membranes. This proprietary technology, incorporating nano-particles, delivers superior filtration performance and energy savings.

Recognizing TFN’s potential, LG Chem acquired NanoH2O™ in 2014 and transferred the entire production line to South Korea, continuing to develop and refine this cutting-edge technology.

2.1. Thin Film Nanocomposite (TFN) technology

Thin Film Nanocomposite (TFN) is an advanced RO membrane manufacturing technology that enhances membrane performance by incorporating nano-particles into the polyamide surface.

This unique structure increases the water yield by up to 20% and achieves an industry-leading salt rejection rate of up to 99.89%, making it one of the most effective membranes available.

With its nano-material structure for RO membranes, Thin Film Nanocomposite (TFN) technology offers the following outstanding advantages:

- Superior salt rejection of up to 99.89%.

- Enhanced fouling resistance, ensuring long-term durability and stable performance of industrial RO membranes.

- High-quality treated water with reduced operating pressure, saving energy and operational costs.

- Optimized water permeability for improved throughput.

- Reduced system footprint, allowing for more compact installations.

- Improved system stability and operational reliability.

2.2. Types of RO membranes of NanoH2O™

NanoH2O™ RO membranes feature BWRO (Brackish Water Reverse Osmosis) and SWRO (Seawater Reverse Osmosis) models equipped with TFN technology. These membranes deliver high filtration efficiency, exceptional salt rejection, energy savings, and durability, meeting the diverse needs of industrial and residential water treatment.

2.2.1 Seawater RO Membranes (SWRO)

NanoH2O™ SWRO membranes dominate the global market, offering exceptional salt rejection rates and robust performance for seawater desalination.

- LG SW SR, GR, R G2: Next-generation membranes with salt rejection rates of up to 99.89%.

- LG SW ES: Energy-efficient membranes suitable for low TDS water and seasonal salinity variations.

- LG SW GR, SR, R: High-rejection membranes designed for high-TDS water, ensuring superior permeate quality.

2.2.2 Brackish Water RO Membranes (BWRO)

In addition to its superior seawater RO membranes, NanoH2O™ product line includes a full range of membranes designed for various feedwater sources such as brackish water and freshwater. These membranes cater to a wide array of industries, including ultra-pure water for pharmaceuticals, semiconductors, industrial production, boiler operations, wastewater reuse, and drinking water.

- LG BW ES: Energy-saving reverse osmosis membranes.

- LG BW AFR: High salt rejection with anti-fouling properties.

- LG BW R: High salt rejection.

- LG BW R G2: Maximum salt rejection, high flux, and exceptional durability.

- LG BW R Dura: Outstanding contaminant removal and long-lasting performance.

- LG BW AFR G2: Superior fouling resistance, high salt rejection, high flow rates, and excellent durability.

In 2024, LG Chem introduced two innovative BWRO membrane models designed to meet optimized energy and performance demands:

- LG MaxRO R: Delivers exceptional salt rejection, utilizing a 36-mil ultra-low DP feed spacer.

- LG BW MOST/MOST+: Offers the highest flow rate among all BWRO membranes while maximizing energy efficiency.

LG Chem continues to innovate and enhance its proprietary Thin Film Nanocomposite (TFN) technology across all its RO membranes (SWRO and BWRO). Particularly, the BWRO membranes now incorporate advanced anti-fouling technology and improved feed spacer designs, ensuring superior filtration efficiency, cost savings, and stable operations for modern water treatment needs.

Anti-Fouling technology:

Fouling is an inevitable issue during the operation of RO membranes. Depending on the composition of the feedwater, system design, and operational processes, fouling can develop at various levels. This leads to an increase in system pressure, a reduction in water flux through the RO membrane, and a decline in the quality of the treated water.

To address this challenge, LG Chem has successfully developed advanced Anti-Fouling Technology. This innovation is based on its proprietary Thin Film Nanocomposite (TFN) platform. Additionally, the polyamide surface of the membrane is coated with a specialized anti-fouling layer, which significantly enhances fouling resistance and cleaning efficiency.

This breakthrough technology provides the following key benefits:

- Extends the durability of industrial reverse osmosis membranes, ensuring consistently stable filtration performance.

- Produces high-quality treated water at reduced operating pressures, leading to energy and cost savings.

- Decreases the frequency of CIP (Clean-In-Place) cleaning, reducing chemical consumption and minimizing plant downtime.

- Improves the recovery rate of membrane filtration efficiency after CIP cleaning.

Feed Spacer technology improvements:

Under stable operating conditions, the pressure differential within an RO system is influenced by the design of the feed spacer. Key factors include the mesh size, fiber diameter, fiber shape, and the angles between adjacent fibers.

To enhance feed spacer performance, LG Chem’s researchers have tested various configurations to achieve optimal flow dynamics with minimal resistance. These efforts resulted in the development of the 34-mil Low DP Feed Spacer, a significant advancement in spacer design.

The 34-mil Low DP Feed Spacer features an innovative mesh thickness of 34 mil with optimized fiber arrangement and geometry. This design minimizes turbulence and pressure losses while preventing concentration polarization.

- Reduces pressure differentials, improving overall efficiency.

- Enhances filtration performance during operation.

- Slows down the formation of contaminants on the surface of RO membranes.

- Lowers fouling rates, ensuring longer system reliability.

- Improves the effectiveness of chemical cleaning for membranes.

- Decreases the frequency of CIP (Clean-In-Place) processes, reducing chemical costs and minimizing downtime for water treatment plants.

LG Chem has developed the LG MaxRO R, which incorporates a 36-mil Ultra Low DP Feed Spacer.

The 36-mil Ultra Low DP feed spacer features a mesh thickness of 36 mil and an advanced three-layer structure. This design significantly reduces flow turbulence and pressure losses, providing superior stability during operation.

- Reduces pressure differentials more effectively than feed spacers with 28-mil or 34-mil designs.

- Delivers superior water treatment performance.

- Minimizes clogging and optimizes flow dynamics.

- Reduces fouling accumulation on the membrane surface.

- Enhances operational efficiency, even under highly contaminated water conditions, making it ideal for wastewater reuse applications.

3. Pricing for NanoH2O™ commercial and industrial RO membranes

All RO membranes distributed by ATS Water Technology Co., Ltd. are officially imported from LG Chem, ensuring premium quality and reliability. We not only provide high-quality products but also deliver advanced technological solutions, design consultancy, and system optimization services, enabling customers to maximize the value of their systems.

To receive an accurate quotation, please contact ATS Water Technology using the information below or submit your request via our quotation form.

ATS WATER TECHNOLOGY CO., LTD

- Head office: 54/18 Bui Quang La, An Hoi Tay Ward, HCMC, Vietnam

- Branch office: 77 DHT10B, Dong Hung Thuan Ward, HCMC, Vietnam

- Consultation and support: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Social media: Facebook | LinkedIn | YouTube

- Quick contact: Zalo Official | Telegram | WhatsApp

4. ATS Water Technology – Authorized distributor of NanoH2O RO membranes in Vietnam

To maintain consistent water quality and enhance system performance, upgrading from conventional TFC RO membranes to NanoH2O™ TFN RO membranes is the preferred choice.

LG Chem’s proprietary TFN technology offers better filtration efficiency and extended durability, improving system performance without the need for a complete system overhaul. These membranes meet the stringent demands of modern industrial applications.

ATS Water Technology Co., Ltd is a trusted distributor of genuine commercial and industrial RO membranes, chosen by many customers for their exceptional quality and service.

- Authentic products: We are the official distributor of NanoH2O™ RO membranes in Vietnam.

- Extensive experience: Our team has over 15 years of expertise in the industry, offering detailed design consultations, advanced solutions, and reliable systems and equipment for contractors and plants.

- Comprehensive solutions: Beyond industrial RO membranes, we provide a wide range of water treatment equipment, anti-fouling chemicals, and specialized cleaning chemicals for RO/NF/UF membranes to meet diverse customer needs.

- Reliable after-sales services: Our experienced technical team is ready to assist with any arising issues under warranty and beyond, guiding customers in membrane cleaning and maintenance. We also supply genuine replacement parts and accessories.

- Nationwide delivery: RO membrane elements purchased from ATS Water Technology are carefully packed and delivered promptly to your location.

5. FAQs about RO membranes

How can I choose the right RO membrane?

Key factors to consider include the quality of the feedwater, desired output water quality, operating conditions, and membrane size.

Why does the performance of an RO membrane decrease?

Common reasons include fouling, scaling, or substandard feedwater quality.

How can I maintain the performance of an industrial RO membrane?

To maintain optimal performance of RO membranes, it is essential to take the following measures: pre-treating feedwater, conducting regular cleaning and maintenance, monitoring permeate water quality, and replacing membranes when necessary.

We hope this article has provided valuable insights into commercial and industrial reverse osmosis (RO) membranes. If you have any further questions, please do not hesitate to contact ATS Water Technology for detailed consultation.

Solution

Solution  Technology

Technology  Application

Application