Điện thoại

(028) 6258 5368Màng UF

Màng UF

Thông tin về màng lọc UF công nghiệp

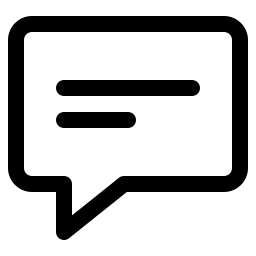

Màng UF (Ultrafiltration) là một trong những công nghệ xử lý nước tiên tiến sử dụng cơ chế lọc vật lý với cấp độ lọc siêu nhỏ để loại bỏ hiệu quả các vi sinh vật, chất rắn lơ lửng và tạp chất keo trong nước. Trong bài viết này, ATS Water Technology sẽ cùng Quý khách tìm hiểu chi tiết về sản phẩm màng lọc UF công nghiệp X-Flow của Pentair – thương hiệu uy tín toàn cầu trong lĩnh vực công nghệ màng lọc.

1. Màng lọc UF là gì?

Với nhu cầu về nguồn nước đạt chuẩn ngày càng cao trong sinh hoạt, sản xuất và ứng dụng y tế, các công nghệ lọc truyền thống như lọc cát, lọc than hoạt tính… đang dần trở nên thiếu linh hoạt và không còn đủ đáp ứng với nguồn nước có nhiều tạp chất vi sinh hay chất hữu cơ. Điều đó khiến màng siêu lọc UF (Ultrafiltration) trở thành một trong những lựa chọn thay thế hiện đại và an toàn.

Về cấu trúc, màng UF bao gồm các sợi màng rỗng có đường kính chỉ vài trăm micromet, bên trong có lỗ lọc với kích thước siêu nhỏ từ 0,01 đến 0,1 micron (10 – 100 nanomet). Nước được đưa vào màng sẽ di chuyển qua lỗ lọc nhờ áp lực. Các phân tử lớn hơn như vi khuẩn, virus, chất keo… sẽ bị giữ lại, còn nước sạch tiếp tục đi qua.

Màng UF có thể lọc tạp chất có kích thước từ 0,01 đến 0,1 micron

2. Công dụng của màng UF

Trong các hệ thống xử lý nước hiện đại, màng lọc UF đóng vai trò là lớp bảo vệ đầu tiên có khả năng loại bỏ vi sinh và các hạt lơ lửng mà không làm thay đổi tính chất hóa học của nước. Nhờ cấu trúc sợi màng với kích thước lọc siêu nhỏ, màng UF giúp làm sạch nước một cách hiệu quả, tiết kiệm chi phí vận hành lâu dài.

Công nghệ màng siêu lọc UF hoạt động chủ yếu dựa trên nguyên lý lọc cơ học, cho phép giữ lại hầu hết các phân tử có kích thước lớn hơn lỗ lọc trong sợi màng. Đối với màng UF, cấp lọc điển hình nằm trong khoảng từ 0,01 đến 0,1 micron (tức 10 – 100 nanomet).

Tuy nhiên, màng UF không loại bỏ được các muối khoáng hòa tan hay chất hữu cơ phân tử nhỏ. Nhờ khả năng giảm độ đục <0,1 NTU và SDI <3, màng lọc nước UF thường được sử dụng làm bước tiền xử lý lý tưởng cho hệ thống RO, giảm thiểu khả năng cáu cặn trên màng RO.

Công dụng của màng UF là loại bỏ vi sinh vật và hạt lơ lửng khỏi nước nhờ cơ chế lọc cơ học, giúp giảm độ đục và chỉ số SDI

3. Phân loại màng siêu lọc UF

Để lựa chọn đúng loại màng UF cho hệ thống xử lý nước, cần nắm rõ các tiêu chí phân loại cơ bản. Mỗi yếu tố ảnh hưởng đến hiệu suất, khả năng vệ sinh và tuổi thọ của màng trong điều kiện vận hành thực tế.

- Theo chất liệu:

- PES (Polyethersulfone): phổ biến trong thiết kế Inside-Out, có khả năng loại bỏ vi sinh vật cao, dễ rửa ngược, hoạt động tốt trong dải pH rộng.

- PVDF (Polyvinylidene Fluoride): dùng nhiều cho thiết kế Outside-In, nổi bật với khả năng chịu chlorine cao và độ bền hóa học tốt, nhưng cần sục khí khi rửa.

- Theo hướng dòng lọc:

- Inside-Out: nước đi từ trong ra ngoài sợi màng, lớp lọc được bảo vệ bên trong, ít mài mòn, dễ làm sạch.

- Outside-In: nước đi từ ngoài vào trong, phù hợp nước có tải lượng chất rắn thấp, nhưng dễ bám bẩn và cần thiết kế sục khí.

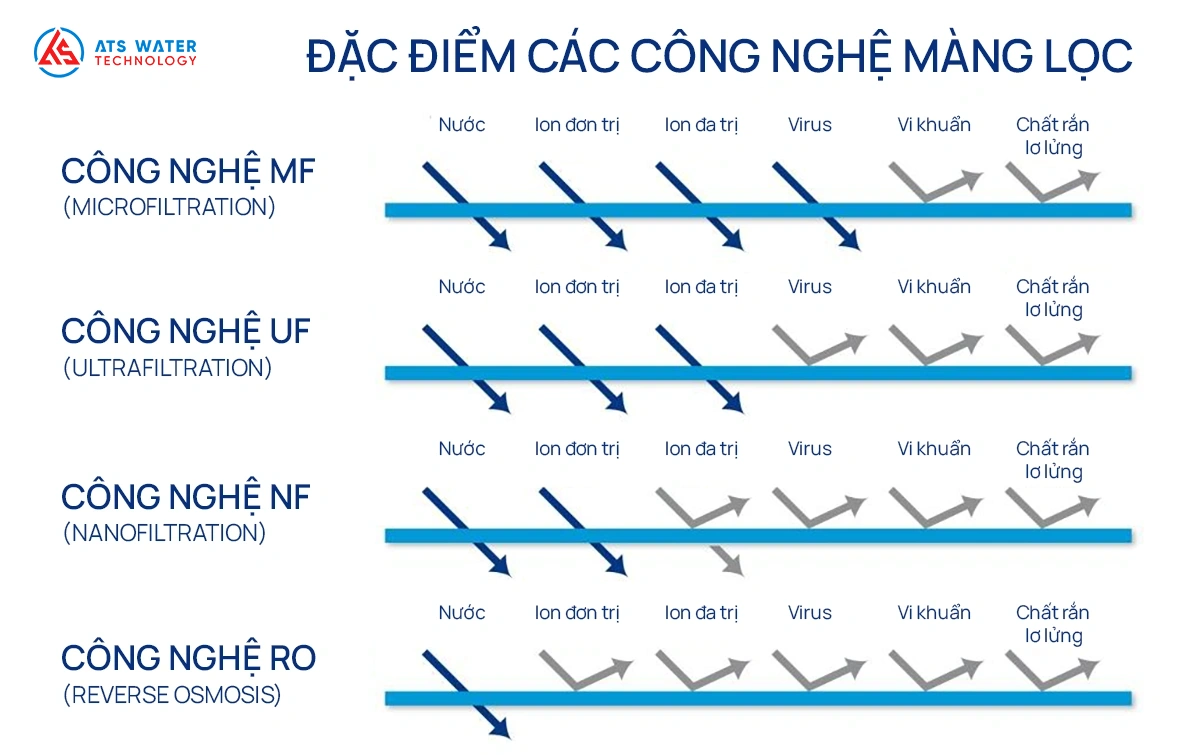

- Theo kích thước đường kính sợi màng:

- Capillary: dạng sợi rỗng nhỏ, mật độ sợi cao, hiệu suất lọc tốt.

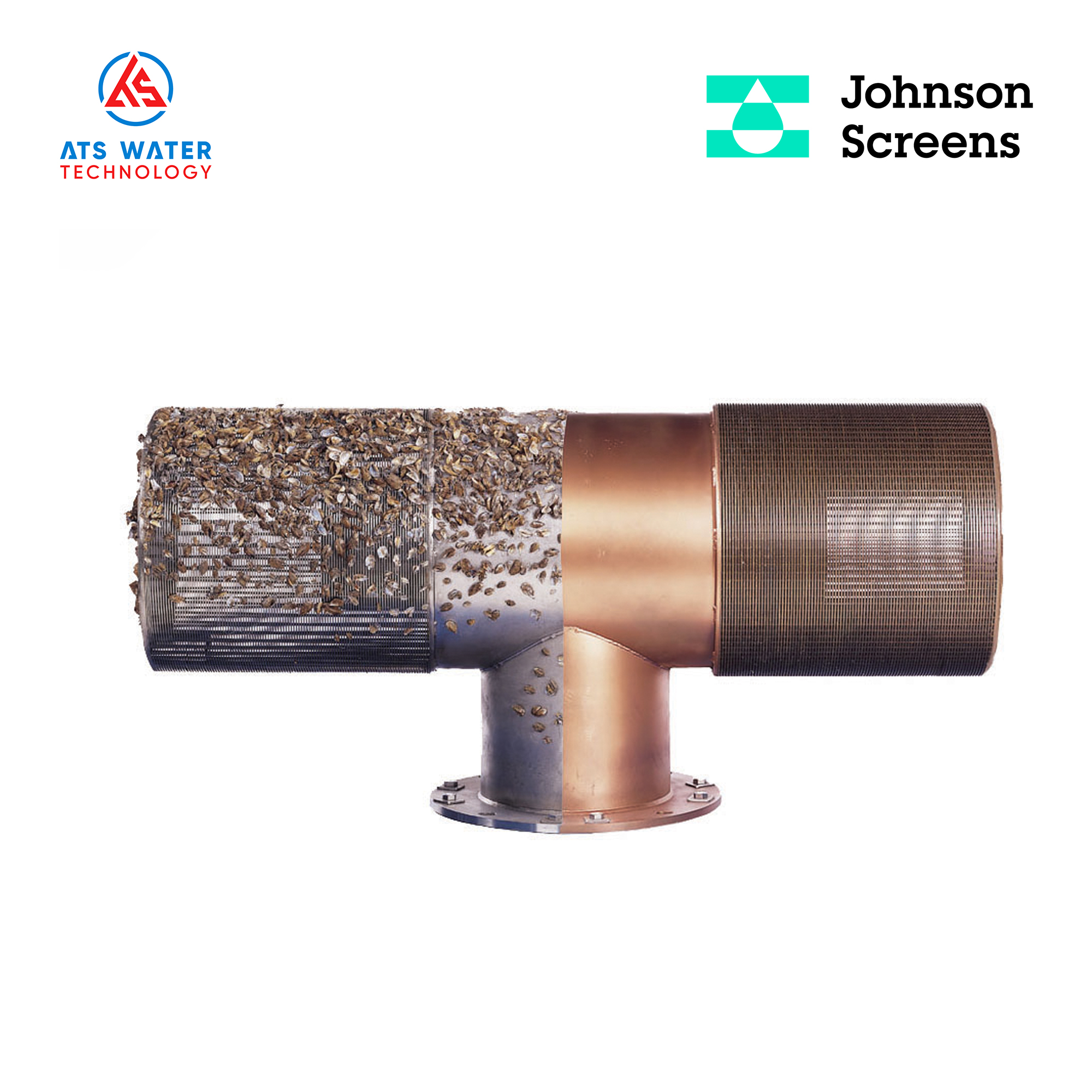

- Tubular: ống lớn, dùng trong nước có hàm lượng chất rắn cao hoặc có dầu.

- Theo kích thước màng: Các module màng lọc nước UF phổ biến có dạng module dài 1,5 m với đường kính 8,7 inch,…

- Theo công suất: Tùy thuộc vào số lượng module và loại hệ thống.

Việc lựa chọn kích thước sợi màng UF phù hợp sẽ ảnh hưởng trực tiếp đến hiệu quả lọc, nguy cơ tắc nghẽn và chi phí vận hành

4. Ưu điểm của màng lọc UF

Màng siêu lọc UF không chỉ giúp xử lý nước hiệu quả mà còn mang lại nhiều lợi thế về vận hành, chi phí và độ bền. Nhờ thiết kế thông minh và cấu trúc vật liệu tối ưu, UF là giải pháp phù hợp cho các hệ thống nước hiện đại, đặc biệt là khi yêu cầu chất lượng nước đầu ra cao.

Một số ưu điểm nổi bật của màng UF:

- Chất lượng nước cao: Loại bỏ hiệu quả vi khuẩn, virus, chất rắn lơ lửng (TSS), đảm bảo nước đạt tiêu chuẩn cấp sinh hoạt, thực phẩm và dược phẩm.

- Tiết kiệm không gian: Thiết kế nhỏ gọn, mô-đun hóa, phù hợp lắp đặt trong khu vực hạn chế diện tích, dễ mở rộng công suất.

- Chi phí vận hành thấp: Tiêu thụ năng lượng thấp hơn RO, ít bảo trì, thời gian vận hành liên tục cao, giảm chi phí vận hành tổng thể.

- Thân thiện môi trường: Cho phép tái sử dụng nước sau xử lý cho mục đích công nghiệp, tưới tiêu, hoặc cấp nước sinh hoạt sau xử lý bổ sung.

Nhờ những lợi ích này, UF đang dần thay thế các công nghệ lọc truyền thống trong nhiều ứng dụng từ nước uống đến công nghiệp.

Màng lọc UF giúp nâng cao chất lượng nước đầu ra nhờ khả năng loại bỏ hiệu quả vi khuẩn, virus và chất rắn lơ lửng

5. Ứng dụng của màng UF công nghiệp

Nhờ hiệu suất lọc vượt trội, màng UF được ứng dụng linh hoạt trong nhiều ngành và hệ thống xử lý nước hiện đại. Từ nước sinh hoạt đến nước cấp cho công nghiệp, từ tiền xử lý RO đến tái sử dụng nước thải, UF luôn đóng vai trò quan trọng trong việc kiểm soát chất lượng nước.

Một số ứng dụng điển hình của màng UF công nghiệp:

- Xử lý nước cấp cho đô thị, tòa nhà, khách sạn, resort.

- Tiền xử lý cho hệ thống RO xử lý nước lợ, nước ngầm hoặc nước biển.

- Tái sử dụng nước thải sau xử lý bậc 2 hoặc bậc 3.

- Lọc nước trong ngành thực phẩm – đồ uống, sản xuất rượu, nước giải khát.

- Ứng dụng trong công nghiệp điện tử, hóa chất, dược phẩm.

- Xử lý nước cho hệ thống lò hơi, tháp giải nhiệt, công nghệ sinh học.

Màng UF công nghiệp được ứng dụng rộng rãi trong xử lý nước cấp, tiền xử lý RO và tái sử dụng nước thải…

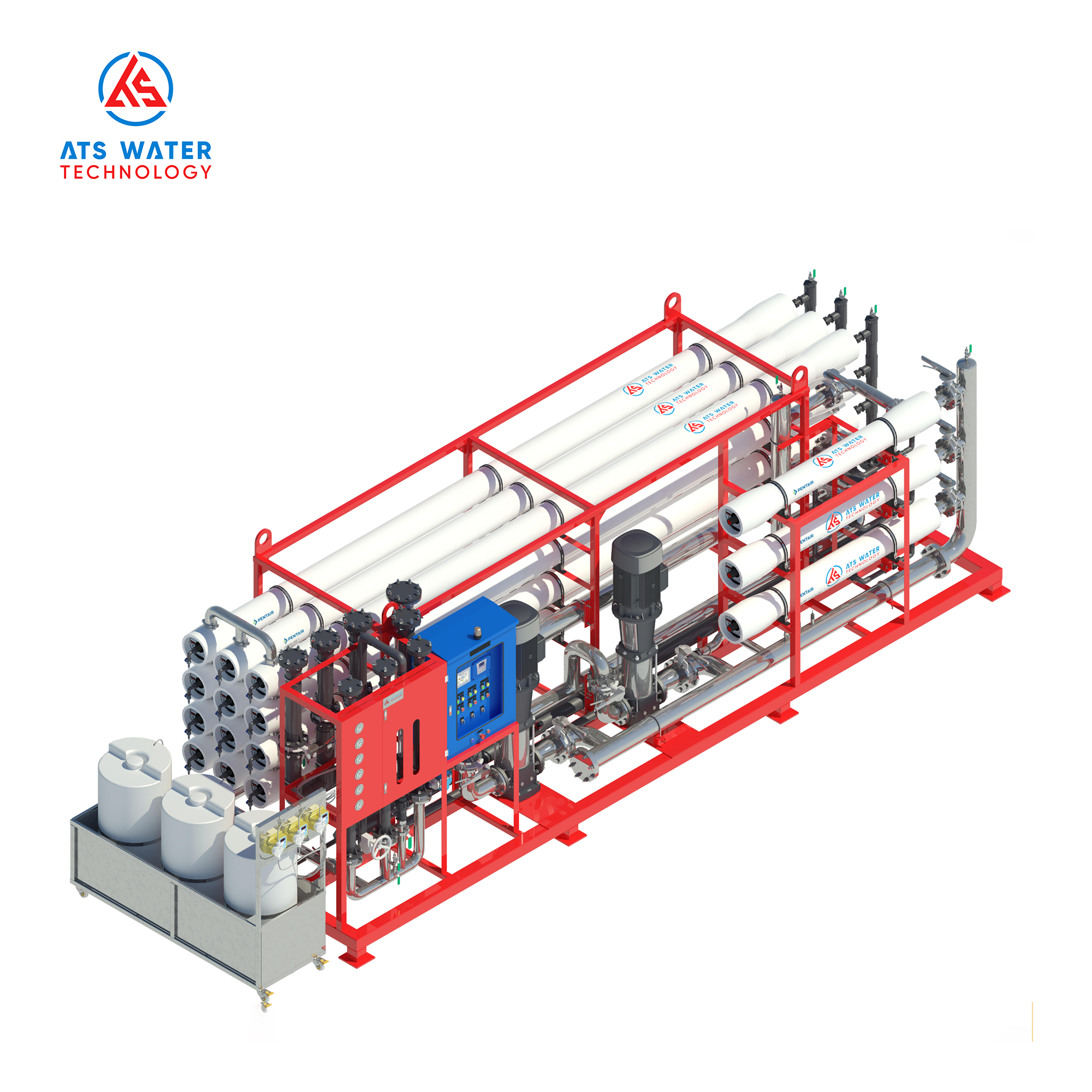

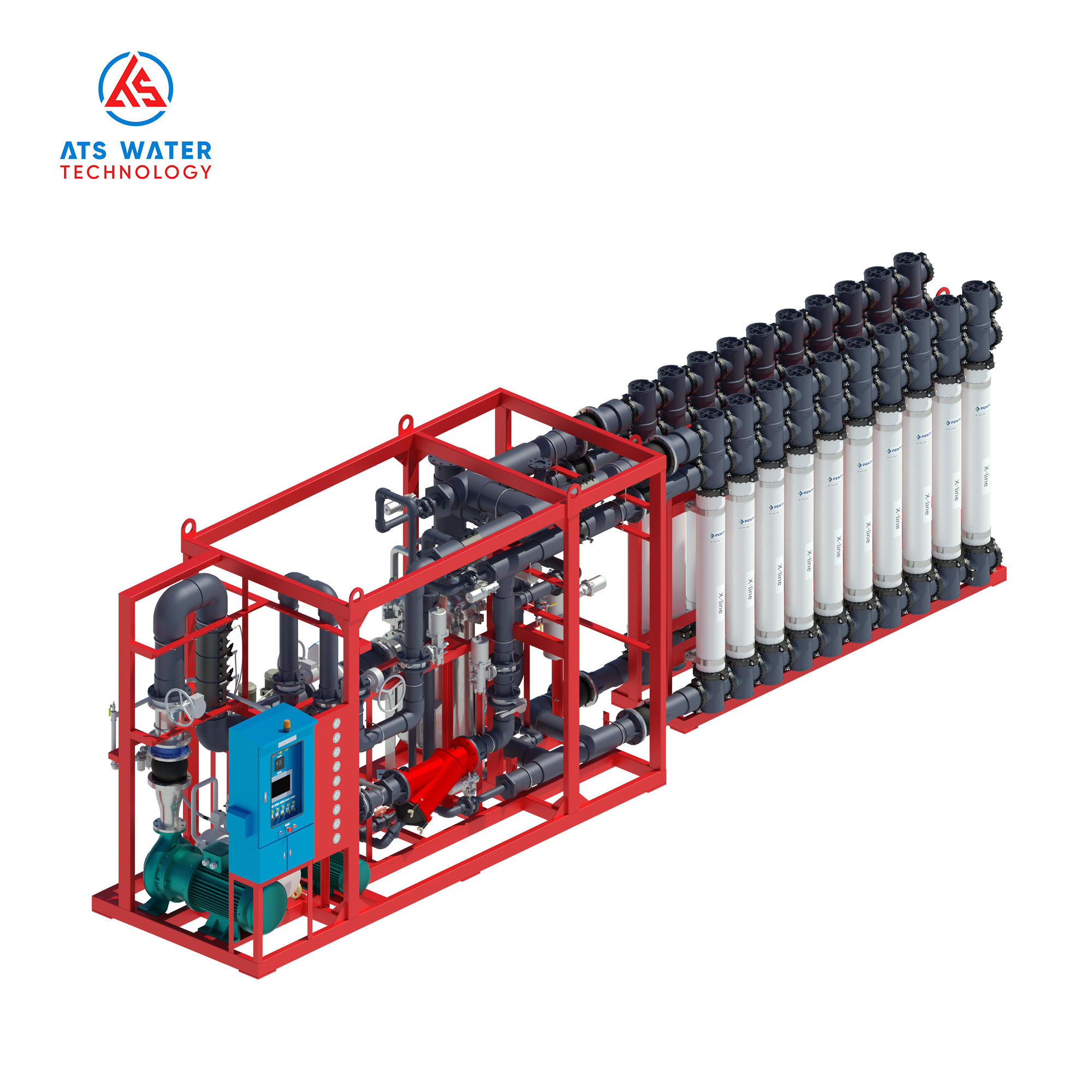

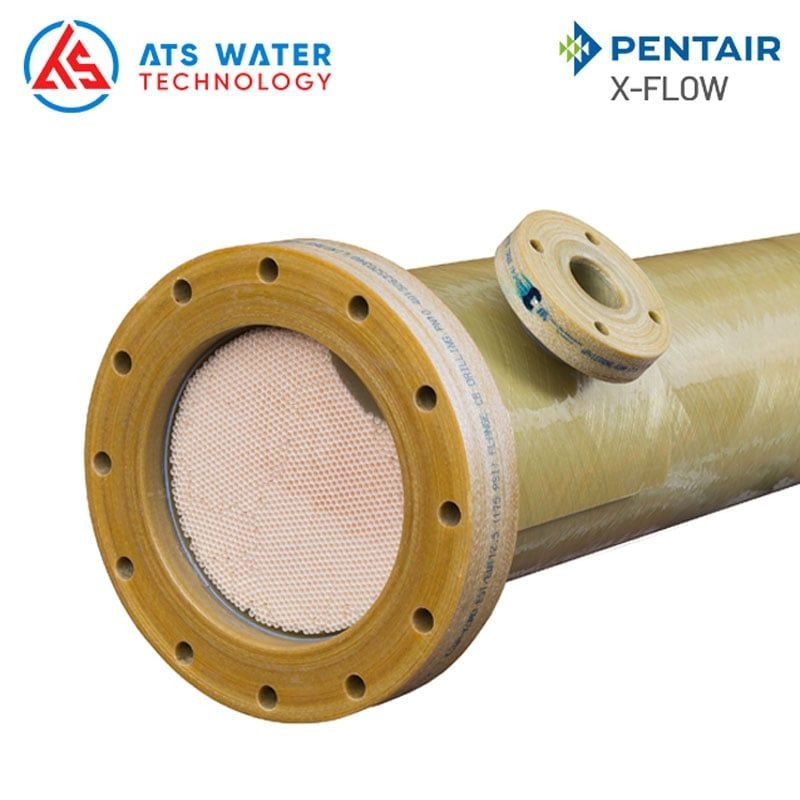

6. Giới thiệu màng UF X-Flow (Pentair)

Màng lọc nước UF công nghiệp thương hiệu X-Flow do tập đoàn Pentair (Hoa Kỳ) phát triển là một trong những giải pháp màng siêu lọc công nghiệp được sử dụng rộng rãi trên toàn cầu. Với hơn 30 năm kinh nghiệm trong lĩnh vực xử lý nước, Pentair cung cấp các dòng sản phẩm màng PES Inside-Out chất lượng cao, đảm bảo hiệu quả xử lý và tuổi thọ vận hành lâu dài.

Một số đặc điểm nổi bật nhất của màng lọc UF công nghiệp X-Flow bao gồm:

- Vật liệu màng bằng Povidone (PVP), Polysulfone (PSU), Polyethersulfone (PES) và Polyvinylidene Fluoride (PVDF), cấu trúc dạng vi xốp cho hiệu suất cao và chống bám bẩn rất tốt.

- Thiết kế kiểu lọc Inside-Out giúp tối ưu quá trình rửa ngược mà không cần sục khí.

- Loại bỏ hiệu quả vi khuẩn (LOG 6) và virus (LOG 4), nước thành phẩm có độ đục < 0,1 NTU và SDI < 3.

- Mật độ sợi cao, thể tích rỗng thấp, tăng hiệu quả lọc và tiết kiệm năng lượng.

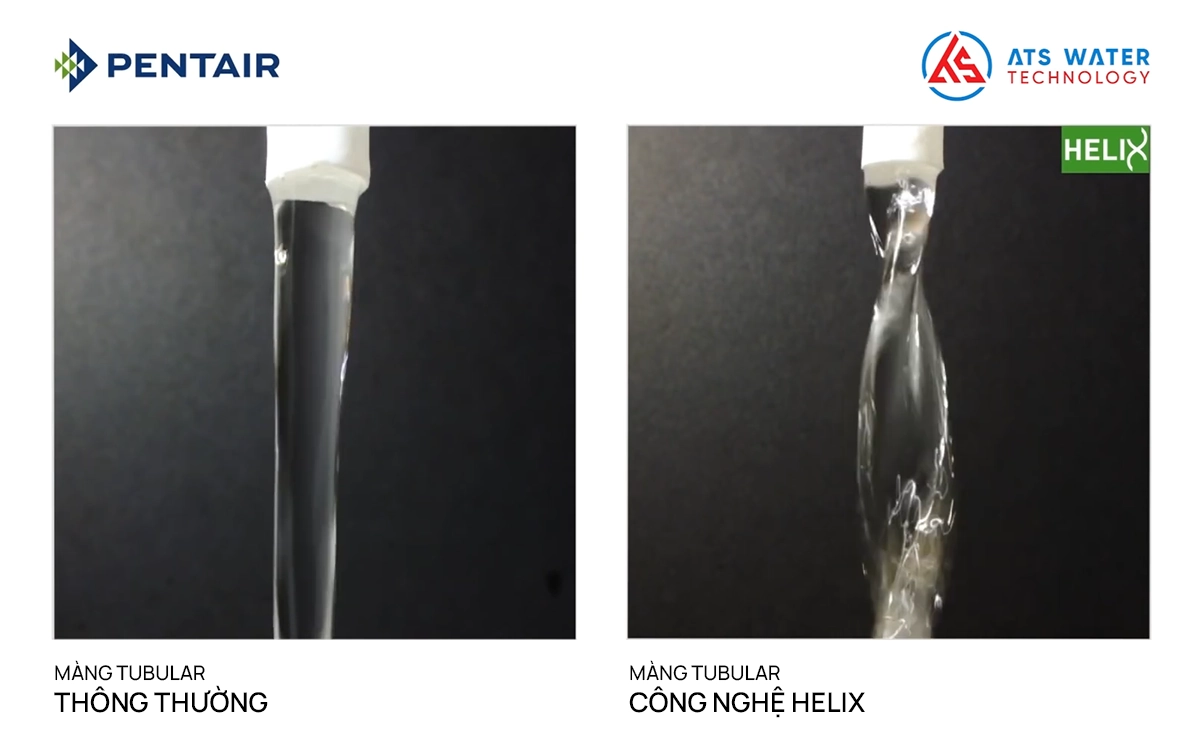

- Ứng dụng công nghệ Helix tiên tiến, giúp tăng cường khả năng xáo trộn dòng nước cấp vào ngay trên thành màng và liên tục loại bỏ chất rắn, bùn bám bên trong sợi màng ở tốc độ dòng chảy chéo (cross-flow) thấp.

Công nghệ Helix giúp xáo trộn dòng nước, giảm bám bẩn bên trong sợi màng

7. Báo giá màng lọc UF X-Flow (Pentair)

Giá thành của màng UF X-Flow phụ thuộc vào nhiều yếu tố kỹ thuật và yêu cầu cụ thể của từng hệ thống. Để đảm bảo hiệu quả đầu tư, doanh nghiệp cần lựa chọn đúng loại module, cấu hình lắp đặt và công suất phù hợp với đặc điểm nguồn nước.

Một số yếu tố ảnh hưởng đến giá:

Do tính đặc thù của từng ứng dụng, Pentair không niêm yết giá cố định trên thị trường. Để nhận báo giá chính xác, Quý khách nên liên hệ trực tiếp với Công ty TNHH Công Nghệ Nước ATS (ATS Water Technology) để được tư vấn kỹ thuật, cấu hình tối ưu và báo giá minh bạch.

Khách hàng có thể kiểm tra thông tin ATS Water Technology là đại lý chính thức của Pentair tại Việt Nam trên website chính thức của hãng: tại đây.

Liên hệ với ATS Water Technology để được báo giá màng lọc UF và tư vấn sản phẩm phù hợp

8. ATS Water Technology – Đơn vị phân phối màng UF X-Flow chính hãng

Lựa chọn nhà phân phối uy tín là bước quan trọng giúp đảm bảo chất lượng màng UF cũng như hiệu quả vận hành hệ thống. Tại Việt Nam, Công ty TNHH Công Nghệ Nước ATS (ATS Water Technology) là đơn vị phân phối chính hãng màng UF X-Flow của Pentair (Hoa Kỳ) – thương hiệu toàn cầu trong lĩnh vực công nghệ màng lọc.

ATS Water Technology cung cấp đầy đủ các dòng sản phẩm UF của Pentair, kèm theo dịch vụ tư vấn giải pháp hiệu quả, công nghệ tiên tiến, kỹ thuật chuyên sâu. Với đội ngũ kỹ sư giàu kinh nghiệm và hệ thống kho hàng sẵn có, chúng tôi cam kết mang đến cho Quý khách những giải pháp xử lý nước tối ưu, hiệu quả và bền vững.

ATS Water Technology là đơn vị phân phối chính hãng màng UF X-Flow của Pentair tại Việt Nam

9. Những câu hỏi thường gặp về màng lọc UF công nghiệp

Màng lọc UF có tốt không?

Có. Màng UF là giải pháp hiệu quả để loại bỏ các vi sinh vật gây hại và tạp chất rắn lơ lửng mà không dùng đến hóa chất. Đặc biệt, màng X-Flow của Pentair có thể loại bỏ đến LOG 6 (99,9999%) vi khuẩn và LOG 4 (99,99%) virus chỉ nhờ vào cơ chế lọc vật lý, đồng thời giúp giảm đáng kể độ đục và SDI của nước.

Làm sao để lựa chọn màng UF phù hợp với doanh nghiệp?

Lựa chọn loại màng lọc UF công nghiệp cần căn cứ vào nhiều yếu tố: chất lượng nước đầu vào (Độ đục, TSS), yêu cầu chất lượng nước đầu ra, loại vật liệu (PES hoặc PVDF), hướng dòng lọc (Inside-Out hoặc Outside-In), chi phí đầu tư và bảo trì.

Các yếu tố nào ảnh hưởng đến hiệu suất của màng UF công nghiệp?

Hiệu suất của màng UF phụ thuộc vào chất lượng nước đầu vào, thông lượng lọc, áp suất vận hành , tần suất rửa ngược và quy trình vệ sinh hóa học (CEB hoặc CIP).

Như vậy, màng lọc UF công nghiệp X-Flow của Pentair (Hoa Kỳ) là lựa chọn lý tưởng cho các hệ thống xử lý nước hiện đại, giúp loại bỏ vi sinh hiệu quả, đảm bảo độ đục thấp và bảo vệ hệ thống RO phía sau. Nếu Quý khách hàng cần tư vấn chuyên sâu hoặc báo giá cụ thể cho từng ứng dụng, đừng ngần ngại liên hệ với đội ngũ kỹ thuật của ATS Water Technology để được hỗ trợ nhanh chóng và chính xác nhất.

CÔNG TY TNHH CÔNG NGHỆ NƯỚC ATS

- Trụ sở chính: 54/18 Bùi Quang Là, P. An Hội Tây, TP. HCM

- Chi nhánh: 77 ĐHT10B, P. Đông Hưng Thuận, TP. HCM

- Tư vấn hỗ trợ: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Mạng xã hội: Facebook | LinkedIn | Zalo Official

Giải pháp

Giải pháp  Công nghệ

Công nghệ  Ứng dụng

Ứng dụng