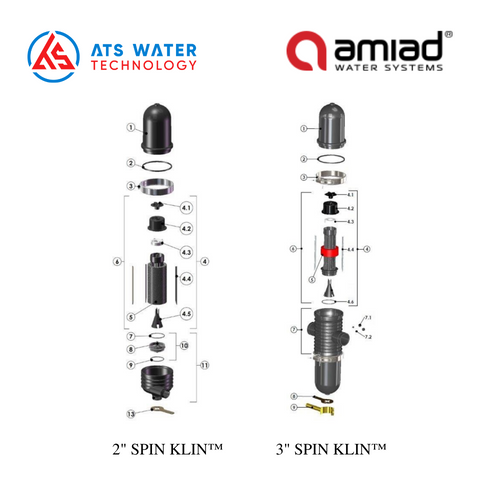

2" SPIN KLIN™

ATS Water Technology offers the 2″ Spin Klin™, which is a modular, all polymeric automatic disc filtration system for industrial applications. The filters are based on our innovative disc technology that captures and retains a large amount of solids. Its unique and efficient hydraulic self-cleaning backwash mechanism requires low water consumption and saves energy demands.

- Technology: Disc

- Types: Automatic

- Filtration Degrees: 10 - 400 micron

- Flow rate: 10 - 90 m3/h

Download ARKAL 2" Spin Klin™ IOM

Download ARKAL 2" Spin Klin™ Ext. Source IOM

2″ Spin Klin™ delivers micron-precise depth filtration and long-term operation with minimal maintenance . It is simple to operate, has a short automatic backwash and permanently eliminates the need to replace filter media.

FEATURES

- Micron-precise depth filtration of solids innovative disc technology captures and retains large amounts of solids

- Long-term operation with minimal maintenance

- Easy and simple operation

- Short automatic backwash with regulated water volume for a small water footprint

- Permanently eliminates the need to replace filter media

- Compact design

GENERAL

The Arkal 2”- 3” SpinKlinTM series are modular, all polymeric, automatic disc filters with a patented self-cleaning backwash mechanism.

The 2”- 3” SpinKlinTM systems range in flow rates from 10 m3/h (44 GPM) to 200 m3/h (880 GPM) with filtration degrees ranging from 20 - 400 micron. Inlet/Outlet from 80 - 200 mm (3”- 8”) diameter.

THE FILTRATION PROCESS

The discs are stacked on the SpinKlinTM spine and assembled according to pre-determined water filtration requirements. During filtration, the discs are compressed by means of a pre-loaded spring and differential pressure, forcing the water to pass through the grooved disc surface, thus trapping the solids.

THE BACKWASH PROCESS

Activated by a pre-determined time trigger or differential pressure, the system enters backwash mode. The inlet valve port shuts while the drain valve port opens. During the backwash process, pressure is released and the spine’s piston elevates, releasing the compression on the discs. Tangential jets of filtered water are then forced through the nozzles positioned along the spine. At this stage the discs spin freely, loosening the trapped solids which are then flushed out. During the flushing cycle each filter pod is backwashed sequentially, while the other pods continue to supply filtered water downstream. When a pod begins the backwash cycle, the system valves automatically reverse the flow in the pod, allowing filtered downstream pressurized water to backwash the filter.

EXTERNAL SOURCE BACKWASH

Each filter is backwashed sequentially, while the other filters continue to supply filtered water downstream. In each backwashed filter the inlet & outlet valves automatically close and the drain & external source valves automatically open. Pressurized filtered water from the external source header enters the backwashed filter through its outlet port and backwashes it.

• Higher energy for low operating pressure applications and fine filtration degrees

AIR AIDED BACKWASH (FOR 2” SPINKLINTM SYSTEMS ONLY)

Main benefits:

- Enhanced cleaning power, especially on fine filtration degrees

- Less backwash water volume

- Low pressure operation

- Reduced backwash time per filter pod (<10 sec)

- The air and water mix at a minimum pressure of 2.5 bar generates the optimal cleaning performance in SpinKlinTM technology

During the flushing cycle, each filter pod is backwashed sequentially while the other pod continues to supply filtered water downstream. When a pod begins the backwash cycle, the valves automatically reverse the flow in the pod, and open the air valve, allowing compressed air to push the filtered water stored in the accumulator through the backwash manifold and into the SpinKlinTM filter being backwashed.

Each backwash cycle requires a time delay to allow the water tank to be filled with clean water and air, making the total backwash duration longer than in regular systems.

A clean & dry air pressure source is necessary to operate the filtration system (supplied by the customer).

SpinKlinTM MODELS

- SK 2” Batteries

- SK 2” Batteries External

- SK 2” Batteries Air Aided

Arkal Spin Klin™ Short Clip

Arkal Spin Klin™ Animation