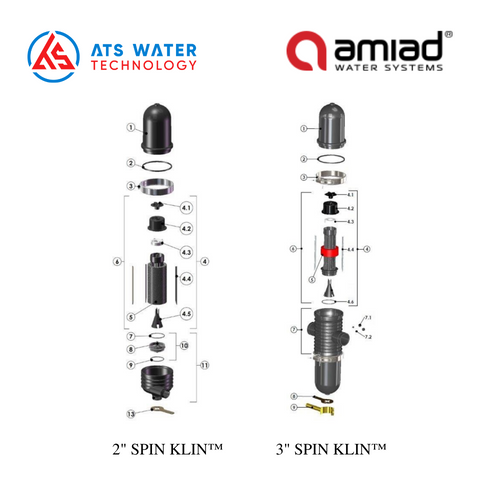

3" SPIN KLIN™

ATS Water Technology offers the 3″ Spin Klin™, which is a modular, all polymeric automatic disc filtration system for industrial applications. The filters are based on our innovative disc technology that captures and retains a large amount of solids. Its unique and efficient hydraulic self-cleaning backwash mechanism requires low water consumption and saves energy demands.

- Technology: Disc

- Types: Automatic

- Filtration Degrees: 10 - 400 micron

- Flow rate: 20 - 180 m3/h

3″ Spin Klin™ delivers micron-precise depth filtration and long-term operation with minimal maintenance . It is simple to operate, has a short automatic backwash and permanently eliminates the need to replace filter media.

FEATURES

- Micrometer-accurate depth filtration of solids

- Innovative lens technology that has a great

- Catches and retains amount of solids

- Long-term operation with minimal maintenance

- Easy handling

- Short automatic backwash with regulated

- Water volume for low water consumption

- Permanently eliminates the need to replace filter media

- Compact design

GENERAL

The Arkal 2 ”- 3” Spin KlinTM series is a modular, automatic disc filtration system made entirely of plastic. It has a patented, self-cleaning backwash mechanism.

The 2 ”- 3” Spin KlinTM systems cover throughput rates from 10 m3 / h (44 gpm) to 200 m3/h (880 gpm) with filter fineness of 10 - 400 microns. Inlet / outlet diameters from 80 - 200 mm (3 ”- 8”).

THE FILTRATION PROCESS

The discs are stacked and mounted on the Spin KlinTM disc carrier in accordance with the specified requirements for water filtration. During the filtration, the discs are compressed by a pretensioned spring and the differential pressure. This forces the water through the notched disc surface where the solids are retained.

THE BACKWASH PROCESS

After a specified time or triggered by the differential pressure, the system switches to backwash mode. The inlet valve is closed and the drain valve is opened. During the backwash process, the pressure is released and the piston of the Spin KlinTM disc carrier is raised to relax the discs. Filtered water is then pressed in jets tangentially through nozzles along the Spin KlinTM disc carrier. In this phase the disks are freely rotatable and release the settled solids, which are then flushed out. During the rinse cycle, the individual solids are backwashed one after the other, the other filter housings continue to supply filtered water. When the backwash cycle begins for a given filter housing, the system valves automatically reverse the flow direction in the rack so that the filter is backwashed with clean water under pressure.

EXTERNAL SOURCE BACKWASH OPTION

The individual filter housings are backwashed in sequence, while the other filter housings continue to supply filtered water. The inlet and outlet valves on each flushed filter close automatically and the valves for and the external source are automatically opened. Filtered water from the line of the external source is fed under pressure into the outlet connection of the backwashed filter and flushes it.

- Higher energy for applications with lower operating pressure and finer filtration.

Spin KlinTM Models

- SK 3” Batteries

- SK 3” Batteries External Source

Arkal Spin Klin™ Short Clip

Arkal Spin Klin™ Animation